Abstract

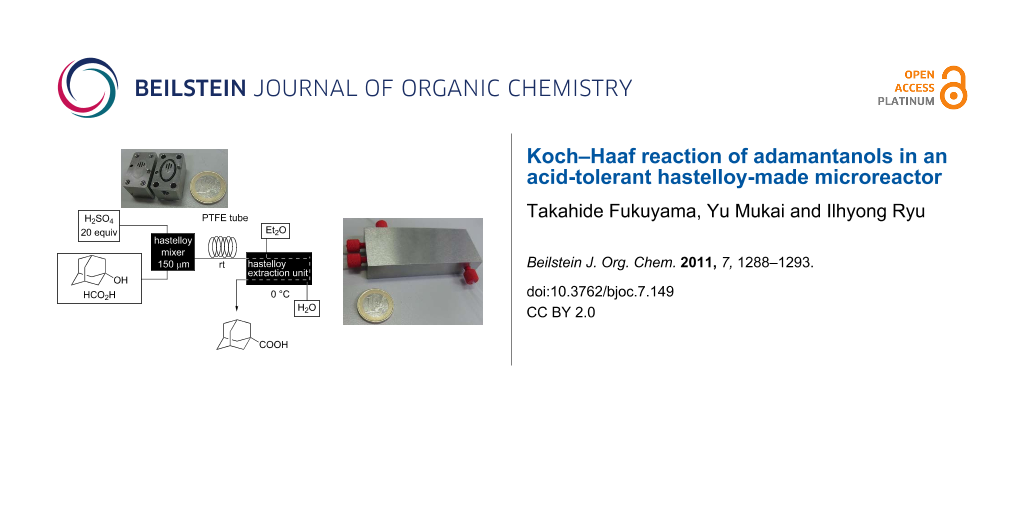

The Koch–Haaf reaction of adamantanols was successfully carried out in a microflow system at room temperature. By combining an acid-tolerant hastelloy-made micromixer, a PTFE tube, and a hastelloy-made microextraction unit, a packaged reaction-to-workup system was developed. By means of the present system, the multigram scale synthesis of 1-adamantanecarboxylic acid was achieved in ca. one hour operation.

Graphical Abstract

Introduction

The recent evolution of microreactor technology has allowed synthetic chemists to use this precisely sophisticated reaction apparatus in place of the well-established glassware batch flask [1-10]. Microreactors are expected to have a significant impact on chemical synthesis and production because of their many advantageous characteristics, such as highly efficient mixing, efficient heat transfer ability, precise control over the residence time, and high operational safety. We have studied and developed practical organic syntheses using flow microreactors, and we have reported thus far examples of Pd-catalyzed coupling reactions [11-13], radical reactions [14-16], and photoreactions [17-21].

Carbonylation reactions are a powerful tool for the introduction of carbon monoxide into organic molecules, and we also reported that Pd-catalyzed carbonylation [13] and radical carbonylation [16] could be successfully carried out in a continuous microflow system with higher efficiency than in a batch autoclave system. In this study, we focused on the carbonylation of carbocation intermediates carried out in a continuous microflow system [22-24]. The Koch–Haaf reaction [25], that is the carbonylation of alcohols or olefins with formic acid in the presence of a strong acid, is an important reaction for the preparation of carboxylic acids, which are widely used in organic synthesis [26-31]. Since the Koch–Haaf reaction is highly exothermic, the reaction is typically carried out at controlled temperature by means of a cooling bath, such as an ice bath, and with carefully controlled slow addition of reagents through an addition funnel. The temperature control causes a serious problem especially for large scale synthesis. Herein, we report that the Koch–Haaf reaction in a microflow reactor can be carried out at room temperature without any cooling equipment. The employed hastelloy-made microreactor system was compatible with corrosive (strongly acidic) conditions and confirmed for gram scale (7.1 g) synthesis of 1-adamantanecarboxylic acid in ca. 1 h operation.

Results and Discussion

The carbonylation reaction of 1-adamantanol (1a) was investigated in a microflow system as a model reaction. Since the Koch–Haaf reaction requires the use of concentrated sulfuric acid, an acid-tolerant system is essential. For this study, we employed a combination of a hastelloy-made micromixer (MiChS, β-150H) having 150 μm reactant inlet holes and 200 μm × 300 μm channels (Figure 1), and a PTFE tube (1.0 mm i.d. × 3 m, inner volume: 2.36 mL) as a residence time unit. To this reactor system, a hastelloy-made microextraction unit (a flow-workup system) was attached (Figure 2 and Figure 3). The microextraction unit has three inlets and one outlet (channel size: 1 mm i.d. × 14 cm). The reaction mixture was mixed at T-shaped junctions with Et2O and water, and a biphasic mixture was collected from the outlet.

![[1860-5397-7-149-1]](/bjoc/content/figures/1860-5397-7-149-1.jpg?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: Hastelloy-made micromixer (MiChS β-150H).

Figure 1: Hastelloy-made micromixer (MiChS β-150H).

Figure 2: Hastelloy-made microextraction unit.

Figure 2: Hastelloy-made microextraction unit.

![[1860-5397-7-149-3]](/bjoc/content/figures/1860-5397-7-149-3.jpg?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Acid-tolerant microflow system used for the Koch–Haaf reaction.

Figure 3: Acid-tolerant microflow system used for the Koch–Haaf reaction.

1-Adamantanol (1a) dissolved in HCOOH (flow rate: 0.30 mL/min) and 98% H2SO4 (flow rate: 0.88 mL/min) were mixed in the micromixer at room temperature, and the resulting reaction mixture was fed into the PTFE tube and then into the extraction unit, in which Et2O (flow rate: 2.5 mL/min) and water (2 mL/min) were introduced to extract the carbonylation product and remove excess acids (Scheme 1). The biphasic mixture was collected in a flask and the ether layer was concentrated in vacuo. 1-Adamantanecarboxylic acid (2a) was obtained in 89% isolated yield after purification by silica gel column chromatography. While the residence time was a priori expected to be 2 min based on the total flow rate of the reagents and inner volume of the residence time unit, the observed residence time was 1.5 min due to a plug flow by the CO gas generated.

Scheme 1: Synthesis of 1-adamantanecarboxylic acid (2a) in a microflow system.

Scheme 1: Synthesis of 1-adamantanecarboxylic acid (2a) in a microflow system.

For comparison, we also carried out the batch reaction in a 50 mL glass flask on 4 mmol scale to give 2a in 92% yield. In the batch reaction, the careful addition of a solution of 1a in formic acid over a period of 5 min and cooling in an ice bath were necessary to achieve good results. Indeed, without a cooling bath, we observed that the temperature of the reaction mixture rose up to 50–60 °C. It is therefore remarkable that the reaction in the microflow system can be performed successfully at room temperature without any cooling unit.

We then investigated the reaction of some other adamantanols, such as that of 2-adamantanol (1b) and 2-methyl-2-adamantanol (1c) (Scheme 2). The reaction of 1b in a microflow system gave a mixture of 2-adamantanecarboxylic acid (2b) and 1-adamantanecarboxylic acid (2a) (82% total yield, 2b:2a = 58:42), in which the latter compound originated from the isomerized tertiary cation, which derived from the initially formed secondary cation. The batch reaction gave a mixture of 2b and 2a in 65% total yield with a greater proportion of the rearranged product (2b:2a = 14:86). The reaction of 2-methyl-2-adamantanol (1c) resulted in a mixture of the carboxylated products, 2c, 2c', and 2c'' in 97% total yield (2c:2c':2c'' = 23:53:24). The batch reaction resulted in an inferior yield with more of the rearranged products (83% yield, 2c:2c':2c'' = 19:62:19). All results are summarized in Table 1.

Scheme 2: Koch–Haaf reaction of 1b and 1c in a microflow system.

Scheme 2: Koch–Haaf reaction of 1b and 1c in a microflow system.

Table 1: Koch–Haaf reactions of adamantanols.a

| Entry | 1 | Reactor | Conditions | Product (yield)b |

|---|---|---|---|---|

| 1 |

|

microflow |

T: 20 °C

flow rate (1a/HCO2H): 0.30 mL/min flow rate (H2SO4): 0.88 mL/min residence time: 2 minc residence time: 1.5 mind |

|

| 2 |

|

batch |

T: 15–20 °C

addition time: 5 min reaction time: 2 min |

|

| 3 |

|

microflow |

T: 20 °C

flow rate (1b/HCO2H): 0.30 mL/min flow rate (H2SO4): 0.88 mL/min residence time: 2 minc residence time: 1 mind |

|

| 4 |

|

batch |

T: 17–20 °C

addition time 5 min reaction time 1 min |

|

| 5 |

|

microflow |

T: 20 °C

flow rate (1c/HCO2H): 0.01 mL/min flow rate (H2SO4): 0.3 mL/min residence time: 20 minc residence time: 2.5 mind |

|

| 6 |

|

batch |

T: 17–20 °C

addition time: 3 min reaction time: 10 min |

|

a1 (4 mmol), HCOOH (6 equiv), H2SO4 (20 equiv); bisolated yield after column chromatography on SiO2; ccalculated; dobserved.

Multigram scale synthesis of 2a from 1a was carried out in a continuous flow reaction. When the reaction of 1a (45 mmol) was performed for 55 min, 7.1 g of 2a was obtained in 88% yield, demonstrating that the present microflow system can be used for multigram scale synthesis without any problems (Scheme 3).

Scheme 3: Multigram scale flow synthesis of 1-adamantanecarboxylic acid (2a).

Scheme 3: Multigram scale flow synthesis of 1-adamantanecarboxylic acid (2a).

Conclusion

In this work, we demonstrated that the Koch–Haaf reaction of adamantanols was successfully carried out in an acid-tolerant microflow system comprising a hastelloy-made micromixer, a PTFE tube, and a hastelloy-made microextraction unit. Unlike in the batch system, the reaction could be carried out at room temperature without any cooling equipment. The employed reaction-to-workup system was useful for the multigram scale synthesis of 1-adamantanecarboxylic acid (2a). We are now expanding the system to other cationic systems and the results will be published in due course.

Experimental

Typical procedure for Koch–Haaf reaction in a microflow system. Multigram scale synthesis of 1-adamantanecarboxylic acid (2a). 1-Adamantanol (1a, 60 mmol, 9.2 g) was dissolved in 96% HCOOH (360 mmol, 16.6 g), and the solution was placed in a 50 mL syringe (22.3 mL), which was then attached to a syringe pump. Concentrated H2SO4 (99%) (1.2 mol, 64 mL) was placed in 100 mL syringe. These liquids were mixed in the hastelloy micromixer (150 μm) (flow rate: 1a in HCOOH = 0.3 mL/min, H2SO4 = 0.88 mL/min). The resulting reaction mixture was then fed into the residence time unit (PTFE tube, 1 mm i.d. × 3 m). The residence time was observed to be 1.5 min. The mixture of products was fed into the hastelloy-made extraction unit, which was cooled by an ice/water bath. Et2O (2.5 mL/min) and water (2 mL/min) were fed into the extraction unit. The mixture that was eluted during the first 5 min was discarded and the portion that followed was collected for 55 min (1a: 45 mmol). The ethereal layer was separated, and washed with 1.4 N KOH aq. The aqueous layer was acidified with 1 N HCl and extracted with Et2O. The organic layer was dried over MgSO4, filtered, and evaporated. 1-Adamantanecarboxylic acid (2a) was obtained in 88% yield as a white solid (7.1 g, mp 171–172 °C). The obtained product was identified by comparison of the 1H NMR and 13C NMR spectra with those of commercially available authentic samples. All other products, 2b, 2c, 2c', and 2c'' were identified by means of NMR spectroscopy by comparison with literature data [32,33].

Typical procedure for Koch–Haaf reaction in a batch reaction system

In a 50 mL two-necked round bottom flask, 99% H2SO4 (80 mmol, 7.85 g) was placed. A solution of 1-adamantanol (1a, 4 mmol, 613 mg) in 96% HCOOH (24 mmol, 1.01 g) was added through a dropping funnel over a period of 5 min, while the temperature of the reaction mixture was maintained at 15–20 °C in an ice/water bath. The reaction mixture was stirred at 15–20 °C for an additional 2 min, poured into ice/water and extracted with Et2O. The ethereal layer was washed with 1.4 N KOH aq, and the aqueous layer was acidified with 1 N HCl and extracted with Et2O. The organic layer was dried over MgSO4, evaporated and purified by column chromatography on SiO2. Compound 2a was obtained in 92% yield (667 mg). The reaction of 1b and 1c was carried out by a similar procedure.

References

-

Wirth, T., Ed. Microreactors in Organic Synthesis and Catalysis; Wiley-VCH: Weinheim, Germany, 2008. doi:10.1002/9783527622856

Return to citation in text: [1] -

Hessel, V.; Renken, A.; Schouten, J. C.; Yoshida, J. Micro Process Engineering; Wiley-VCH: Weinheim, Germany, 2009.

Return to citation in text: [1] -

Mason, B. P.; Price, K. E.; Steinbacher, J. L.; Bogdan, A. R.; McQuade, D. T. Chem. Rev. 2007, 107, 2300–2318. doi:10.1021/cr050944c

Return to citation in text: [1] -

Yoshida, J.; Nagaki, A.; Yamada, T. Chem.–Eur. J. 2008, 14, 7450–7459. doi:10.1002/chem.200800582

Return to citation in text: [1] -

Lin, W.-Y.; Wang, Y.; Wang, S.; Tseng, H.-R. Nano Today 2009, 4, 470–481. doi:10.1016/j.nantod.2009.10.007

Return to citation in text: [1] -

McMullen, J. P.; Jensen, K. F. Annu. Rev. Anal. Chem. 2010, 3, 19–42. doi:10.1146/annurev.anchem.111808.073718

Return to citation in text: [1] -

Webb, D.; Jamison, T. F. Chem. Sci. 2010, 1, 675–680. doi:10.1039/C0SC00381F

Return to citation in text: [1] -

Yoshida, J. Chem. Rec. 2010, 10, 332–341. doi:10.1002/tcr.201000020

Return to citation in text: [1] -

Wegner, J.; Ceylan, S.; Kirschning, A. Chem. Commun. 2011, 47, 4583–4592. doi:10.1039/c0cc05060a

Return to citation in text: [1] -

Fukuyama, T.; Rahman, M. T.; Sato, M.; Ryu, I. Synlett 2008, 151–163. doi:10.1055/s-2007-1000884

Return to citation in text: [1] -

Fukuyama, T.; Shinmen, M.; Nishitani, S.; Sato, M.; Ryu, I. Org. Lett. 2002, 4, 1691–1694. doi:10.1021/ol0257732

Return to citation in text: [1] -

Liu, S.; Fukuyama, T.; Sato, M.; Ryu, I. Org. Process Res. Dev. 2004, 8, 477–481. doi:10.1021/op034200h

Return to citation in text: [1] -

Rahman, M. T.; Fukuyama, T.; Kamata, N.; Sato, M.; Ryu, I. Chem. Commun. 2006, 2236–2238. doi:10.1039/B600970K

Return to citation in text: [1] [2] -

Fukuyama, T.; Kobayashi, M.; Rahman, M. T.; Kamata, N.; Ryu, I. Org. Lett. 2008, 10, 533–536. doi:10.1021/ol702718z

Return to citation in text: [1] -

Wienhöfer, I. C.; Studer, A.; Rahman, M. T.; Fukuyama, T.; Ryu, I. Org. Lett. 2009, 11, 2457–2460. doi:10.1021/ol900713d

Return to citation in text: [1] -

Fukuyama, T.; Rahman, M. T.; Kamata, N.; Ryu, I. Beilstein J. Org. Chem. 2009, 5, No. 34. doi:10.3762/bjoc.5.34

Return to citation in text: [1] [2] -

Fukuyama, T.; Hino, Y.; Kamata, N.; Ryu, I. Chem. Lett. 2004, 33, 1430–1431. doi:10.1246/cl.2004.1430

Return to citation in text: [1] -

Sugimoto, A.; Sumino, Y.; Takagi, M.; Fukuyama, T.; Ryu, I. Tetrahedron Lett. 2006, 47, 6197–6200. doi:10.1016/j.tetlet.2006.06.153

Return to citation in text: [1] -

Sugimoto, A.; Fukuyama, T.; Sumino, Y.; Takagi, M.; Ryu, I. Tetrahedron 2009, 65, 1593–1598. doi:10.1016/j.tet.2008.12.063

Return to citation in text: [1] -

Matsubara, H.; Hino, Y.; Tokizane, M.; Ryu, I. Chem. Eng. J. 2011, 167, 567–571. doi:10.1016/j.cej.2010.08.086

Return to citation in text: [1] -

Tsutsumi, K.; Terao, K.; Yamaguchi, H.; Yoshimura, S.; Morimoto, T.; Kakiuchi, K.; Fukuyama, T.; Ryu, I. Chem. Lett. 2010, 39, 828–829. doi:10.1246/cl.2010.828

Return to citation in text: [1] -

Suga, S.; Nagaki, A.; Yoshida, J. Chem. Commun. 2003, 354–355. doi:10.1039/B211433J

For Friedel–Crafts alkylation with carbocation intermediates using a microreator.

Return to citation in text: [1] -

Tanaka, K.; Motomatsu, S.; Koyama, K.; Tanaka, S.; Fukase, K. Org. Lett. 2007, 9, 299–302. doi:10.1021/ol062777o

For acid-catalyzed dehydration of alcohols via carbocation intermediates in a mircoflow system.

Return to citation in text: [1] -

Brandt, J. C.; Elmore, S. C.; Robinson, R. I.; Wirth, T. Synlett 2010, 3099–3103. doi:10.1055/s-0030-1259075

For Ritter reaction in a microflow system.

Return to citation in text: [1] -

Koch, H.; Haaf, W. Justus Liebigs Ann. Chem. 1958, 618, 251–266. doi:10.1002/jlac.19586180127

Return to citation in text: [1] -

Hoffmann-Emery, F.; Hilpert, H.; Scalone, M.; Waldmeier, P. J. Org. Chem. 2006, 71, 2000–2008. doi:10.1021/jo0523666

Return to citation in text: [1] -

Sorensen, B.; Rohde, J.; Wang, J.; Fung, S.; Monzon, K.; Chiou, W.; Pan, L.; Deng, X.; Stolarik, D.; Frevert, E. U.; Jacobson, P.; Link, J. T. Bioorg. Med. Chem. Lett. 2006, 16, 5958–5962. doi:10.1016/j.bmcl.2006.08.129

Return to citation in text: [1] -

Becker, C. L.; Engstrom, K. M.; Kerdesky, F. A.; Tolle, J. C.; Wagaw, S. H.; Wang, W. Org. Process Res. Dev. 2008, 12, 1114–1118. doi:10.1021/op800065q

Return to citation in text: [1] -

Wan, Z.; Laine, D. I.; Yan, H.; Zhu, C.; Widdowson, K. L.; Buckley, P. T.; Burman, M.; Foley, J. J.; Sarau, H. M.; Schmidt, D. B.; Webb, E. F.; Belmonte, K. E.; Palovich, M. Bioorg. Med. Chem. Lett. 2009, 19, 4560–4562. doi:10.1016/j.bmcl.2009.07.006

Return to citation in text: [1] -

Barton, V.; Ward, S. A.; Chadwick, J.; Hill, A.; O’Neill, P. M. J. Med. Chem. 2010, 53, 4555–4559. doi:10.1021/jm100201j

Return to citation in text: [1] -

Shmailov, A.; Alimbarova, L.; Shokova, E.; Tafeenko, V.; Vatsouro, I.; Kovalev, V. Tetrahedron 2010, 66, 3058–3064. doi:10.1016/j.tet.2010.02.043

Return to citation in text: [1] -

Mukherjee, A.; Wu, Q.; le Noble, W. J. J. Org. Chem. 1994, 59, 3270–3274. doi:10.1021/jo00091a010

Return to citation in text: [1] -

Alford, J. R.; Cuddy, B. D.; Grant, D.; McKervey, M. A. J. Chem. Soc., Perkin Trans. 1 1972, 2707–2713. doi:10.1039/P19720002707

Return to citation in text: [1]

| 1. | Wirth, T., Ed. Microreactors in Organic Synthesis and Catalysis; Wiley-VCH: Weinheim, Germany, 2008. doi:10.1002/9783527622856 |

| 2. | Hessel, V.; Renken, A.; Schouten, J. C.; Yoshida, J. Micro Process Engineering; Wiley-VCH: Weinheim, Germany, 2009. |

| 3. | Mason, B. P.; Price, K. E.; Steinbacher, J. L.; Bogdan, A. R.; McQuade, D. T. Chem. Rev. 2007, 107, 2300–2318. doi:10.1021/cr050944c |

| 4. | Yoshida, J.; Nagaki, A.; Yamada, T. Chem.–Eur. J. 2008, 14, 7450–7459. doi:10.1002/chem.200800582 |

| 5. | Lin, W.-Y.; Wang, Y.; Wang, S.; Tseng, H.-R. Nano Today 2009, 4, 470–481. doi:10.1016/j.nantod.2009.10.007 |

| 6. | McMullen, J. P.; Jensen, K. F. Annu. Rev. Anal. Chem. 2010, 3, 19–42. doi:10.1146/annurev.anchem.111808.073718 |

| 7. | Webb, D.; Jamison, T. F. Chem. Sci. 2010, 1, 675–680. doi:10.1039/C0SC00381F |

| 8. | Yoshida, J. Chem. Rec. 2010, 10, 332–341. doi:10.1002/tcr.201000020 |

| 9. | Wegner, J.; Ceylan, S.; Kirschning, A. Chem. Commun. 2011, 47, 4583–4592. doi:10.1039/c0cc05060a |

| 10. | Fukuyama, T.; Rahman, M. T.; Sato, M.; Ryu, I. Synlett 2008, 151–163. doi:10.1055/s-2007-1000884 |

| 13. | Rahman, M. T.; Fukuyama, T.; Kamata, N.; Sato, M.; Ryu, I. Chem. Commun. 2006, 2236–2238. doi:10.1039/B600970K |

| 17. | Fukuyama, T.; Hino, Y.; Kamata, N.; Ryu, I. Chem. Lett. 2004, 33, 1430–1431. doi:10.1246/cl.2004.1430 |

| 18. | Sugimoto, A.; Sumino, Y.; Takagi, M.; Fukuyama, T.; Ryu, I. Tetrahedron Lett. 2006, 47, 6197–6200. doi:10.1016/j.tetlet.2006.06.153 |

| 19. | Sugimoto, A.; Fukuyama, T.; Sumino, Y.; Takagi, M.; Ryu, I. Tetrahedron 2009, 65, 1593–1598. doi:10.1016/j.tet.2008.12.063 |

| 20. | Matsubara, H.; Hino, Y.; Tokizane, M.; Ryu, I. Chem. Eng. J. 2011, 167, 567–571. doi:10.1016/j.cej.2010.08.086 |

| 21. | Tsutsumi, K.; Terao, K.; Yamaguchi, H.; Yoshimura, S.; Morimoto, T.; Kakiuchi, K.; Fukuyama, T.; Ryu, I. Chem. Lett. 2010, 39, 828–829. doi:10.1246/cl.2010.828 |

| 14. | Fukuyama, T.; Kobayashi, M.; Rahman, M. T.; Kamata, N.; Ryu, I. Org. Lett. 2008, 10, 533–536. doi:10.1021/ol702718z |

| 15. | Wienhöfer, I. C.; Studer, A.; Rahman, M. T.; Fukuyama, T.; Ryu, I. Org. Lett. 2009, 11, 2457–2460. doi:10.1021/ol900713d |

| 16. | Fukuyama, T.; Rahman, M. T.; Kamata, N.; Ryu, I. Beilstein J. Org. Chem. 2009, 5, No. 34. doi:10.3762/bjoc.5.34 |

| 11. | Fukuyama, T.; Shinmen, M.; Nishitani, S.; Sato, M.; Ryu, I. Org. Lett. 2002, 4, 1691–1694. doi:10.1021/ol0257732 |

| 12. | Liu, S.; Fukuyama, T.; Sato, M.; Ryu, I. Org. Process Res. Dev. 2004, 8, 477–481. doi:10.1021/op034200h |

| 13. | Rahman, M. T.; Fukuyama, T.; Kamata, N.; Sato, M.; Ryu, I. Chem. Commun. 2006, 2236–2238. doi:10.1039/B600970K |

| 26. | Hoffmann-Emery, F.; Hilpert, H.; Scalone, M.; Waldmeier, P. J. Org. Chem. 2006, 71, 2000–2008. doi:10.1021/jo0523666 |

| 27. | Sorensen, B.; Rohde, J.; Wang, J.; Fung, S.; Monzon, K.; Chiou, W.; Pan, L.; Deng, X.; Stolarik, D.; Frevert, E. U.; Jacobson, P.; Link, J. T. Bioorg. Med. Chem. Lett. 2006, 16, 5958–5962. doi:10.1016/j.bmcl.2006.08.129 |

| 28. | Becker, C. L.; Engstrom, K. M.; Kerdesky, F. A.; Tolle, J. C.; Wagaw, S. H.; Wang, W. Org. Process Res. Dev. 2008, 12, 1114–1118. doi:10.1021/op800065q |

| 29. | Wan, Z.; Laine, D. I.; Yan, H.; Zhu, C.; Widdowson, K. L.; Buckley, P. T.; Burman, M.; Foley, J. J.; Sarau, H. M.; Schmidt, D. B.; Webb, E. F.; Belmonte, K. E.; Palovich, M. Bioorg. Med. Chem. Lett. 2009, 19, 4560–4562. doi:10.1016/j.bmcl.2009.07.006 |

| 30. | Barton, V.; Ward, S. A.; Chadwick, J.; Hill, A.; O’Neill, P. M. J. Med. Chem. 2010, 53, 4555–4559. doi:10.1021/jm100201j |

| 31. | Shmailov, A.; Alimbarova, L.; Shokova, E.; Tafeenko, V.; Vatsouro, I.; Kovalev, V. Tetrahedron 2010, 66, 3058–3064. doi:10.1016/j.tet.2010.02.043 |

| 25. | Koch, H.; Haaf, W. Justus Liebigs Ann. Chem. 1958, 618, 251–266. doi:10.1002/jlac.19586180127 |

| 22. |

Suga, S.; Nagaki, A.; Yoshida, J. Chem. Commun. 2003, 354–355. doi:10.1039/B211433J

For Friedel–Crafts alkylation with carbocation intermediates using a microreator. |

| 23. |

Tanaka, K.; Motomatsu, S.; Koyama, K.; Tanaka, S.; Fukase, K. Org. Lett. 2007, 9, 299–302. doi:10.1021/ol062777o

For acid-catalyzed dehydration of alcohols via carbocation intermediates in a mircoflow system. |

| 24. |

Brandt, J. C.; Elmore, S. C.; Robinson, R. I.; Wirth, T. Synlett 2010, 3099–3103. doi:10.1055/s-0030-1259075

For Ritter reaction in a microflow system. |

| 16. | Fukuyama, T.; Rahman, M. T.; Kamata, N.; Ryu, I. Beilstein J. Org. Chem. 2009, 5, No. 34. doi:10.3762/bjoc.5.34 |

| 32. | Mukherjee, A.; Wu, Q.; le Noble, W. J. J. Org. Chem. 1994, 59, 3270–3274. doi:10.1021/jo00091a010 |

| 33. | Alford, J. R.; Cuddy, B. D.; Grant, D.; McKervey, M. A. J. Chem. Soc., Perkin Trans. 1 1972, 2707–2713. doi:10.1039/P19720002707 |

© 2011 Fukuyama et al; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)