Abstract

Quite extensive synthetic achievements vanish in the online supporting information of publications on functional systems. Underappreciated, their value is recognized by experts only. As an example, we here focus in on the recent synthesis of multicomponent photosystems with antiparallel charge-transfer cascades in co-axial hole- and electron-transporting channels. The synthetic steps are described one-by-one, starting with commercial starting materials and moving on to key intermediates, such as asparagusic acid, an intriguing natural product, as well as diphosphonate “feet”, and panchromatic naphthalenediimides (NDIs), to finally reach the target molecules. These products are initiators and propagators for self-organizing surface-initiated polymerization (SOSIP), a new method introduced to secure facile access to complex architectures. Chemoorthogonal to the ring-opening disulfide exchange used for SOSIP, hydrazone exchange is then introduced to achieve stack exchange, which is a “switching” technology invented to drill giant holes into SOSIP architectures and fill them with functional π-stacks of free choice.

Graphical Abstract

Introduction

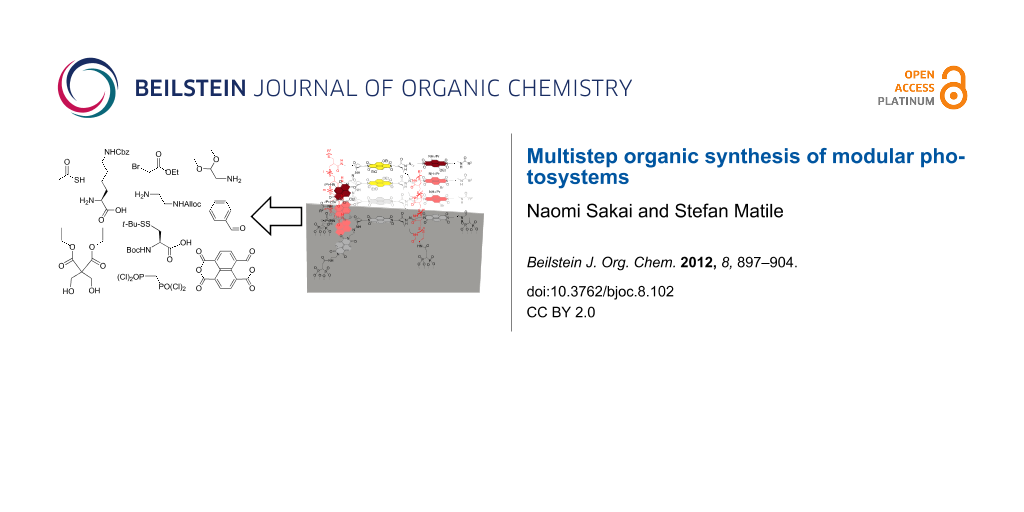

The architecture of photosystem 1 is rather sophisticated, probably as sophisticated as it gets with photosystems today (Figure 1) [1]. It is composed of three co-axial π-stacks that are grown from an indium tin oxide (ITO) surface. With lower frontier molecular orbital (FMO) levels, the “yellow” stacks can transport photogenerated electrons toward the ITO surface along the gradient in their LUMO. With higher FMO levels, the “red” stacks can transport holes along the gradient in their HOMOs in the opposite direction, away from the ITO surface.

![[1860-5397-8-102-1]](/bjoc/content/figures/1860-5397-8-102-1.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: Schematic structure of photosystem 1 on indium tin oxide (ITO, grey) with antiparallel gradients in hole (p, h+) and electron (n, e−) transporting coaxial channels. HOMO (solid) and LUMO levels (dashed) of all components (color coded) are indicated in eV against vacuum (−5.1 eV for Fc/Fc+), including triethanolamine (TEOA), used as mobile hole transporter.

Figure 1: Schematic structure of photosystem 1 on indium tin oxide (ITO, grey) with antiparallel gradients in...

The double-channel architecture 1 with antiparallel redox gradients has been referred to as OMARG-SHJ, that is supramolecular n/p-heterojunctions with oriented multicomponent/color antiparallel redox gradients [2,3]. With n/p contact areas maximized down to the molecular level, photoinduced charge separation (i.e., charge generation) should be as favorable as directional charge translocation (i.e., charge separation) along redox gradients in the molecular channels. With photosystem 1, these high expectations could finally be tested experimentally [1]. OMARG-SHJs turned out to be best quantified with bimolecular charge recombination efficiencies ηBR, that is, losses in photonic energy. Photosystem 1 gave ηBR = 22%; gradient-free controls gave ηBR = 50%; destructive gradients gave ηBR = 76%. These results are very satisfactory. They also confirmed that significant synthetic efforts to build sophisticated functional architectures can be worthwhile. In the original communication, these synthetic efforts completely disappeared in the online supporting information [1]. The fact that results on synthesis are self-explanatory to all and do not require much discussion can be considered as a marvelous illustration of the success of the field. However, to illustrate the frequent lack of appreciation of the synthetic organic chemistry in work on functional systems, the total synthesis of photosystem 1 will be described step-by-step in the following.

Results and Discussion

Synthesis of initiators

Photosystem 1 is constructed from the molecular building blocks 2–6 (Schemes 1-3). Initiator 2 is composed of a central naphthalenediimide (NDI) [4-19] to act as a template for the central stack and two peripheral NDIs to act as templates for stack exchange. They are embedded into hydrogen-bonded networks, to assure self-organization, and four geminal diphosphonates [20,21] for tetravalent anchoring on the ITO surface.

The geminal diphosphonates 7 were synthesized from methylene bis(phosphonic dichloride) 8 (Scheme 1) [20,21]. Conversion with benzyl alcohol and pyridine as a base yielded tetrabenzyl methylene bisphosphonate 9. Activation with sodium hydride and alkylation with ethyl bromoacetate (10) gave ethyl ester 11, and final ester hydrolysis lead to the desired acid 7.

The peripheral NDIs 12, designed to template for stack exchange on initiator 2, were prepared from naphthalenedianhydride (NDA) 13. Microwave-assisted imidation [15] with the two amines 14 and 15 at 140 °C gave the mixed diimide 16 in excellent 66% yield together with the symmetric diimide side products. Amines were liberated by palladium-catalyzed Alloc removal and reacted with acid 7. The obtained amide 17 was deprotected with acid to afford the desired aldehyde 12.

The central NDI 18 of initiator 2, designed to initiate and template for SOSIP, was accessible from NDA 13 as well. The synthesis of NDI 19 by microwave-assisted imidation with Boc-protected lysine 20 has been reported before in the literature [15]. Reaction with Cbz-hydrazine gave the Cbz-protected NDI hydrazide 21. After chemoselective, acid-catalyzed deprotection, the liberated amines were coupled with the Boc-protected cysteine tert-butyl disulfide 22. The obtained amide 23 was treated with TFA for Boc removal and coupled with the geminal diphosphonate foot 7. Deprotection of both hydrazides and diphosphonates in NDI 24 gave 18, which was reacted in situ with NDI 12 to yield initiator 2.

Synthesis of propagators

The synthesis of propagator 3 starts with NDA 13 as well (Scheme 2). Diimidation with Cbz-protected lysine 25 gave the diacid 26. Activation with EDC, HOBt and TEA was followed by the reaction with tert-butyl carbazate under mild conditions. The protected hydrazide 27 was obtained in 59% yield over two steps. The Cbz protecting groups were removed chemoselectively by hydrogenolysis over Pd–C in the presence of acetic acid, and the obtained diamine was reacted with the activated asparagusic acid 28. Hydrazide deprotection in NDI 29 and in situ hydrazone formation with benzaldehyde 30 gave propagator 3.

Scheme 2: Synthesis of propagators 3 and 4.

Scheme 2: Synthesis of propagators 3 and 4.

In contrast to propagator 3, propagator 4 is constructed around a yellow, core-substituted cNDI fluorophore. Nevertheless, the synthesis of this target molecule also starts with NDA 13. Bromination in the core with dibromocyanuric acid (31) afforded an intractable mixture containing the 2,6-dibromo NDA 32 together with lower and higher homologues [16]. However, pure product 33 could be readily isolated from this mixture after transformation of the NDAs into the core-substituted naphthalenetetraesters (cNTEs). Nucleophilic core-substitution with ethanolate gave cNTE 34 as described in the literature [16].

NTE 34 was subjected to basic ester hydrolysis followed by diimidation with lysine 25. From this point, the synthesis of cNDI propagator 4 was analogous to the synthesis of NDI propagator 3. Reaction of EDC-activated diacid 35 with tert-butyl carbazate followed by deprotection of the obtained cNDI 36 and coupling with activated asparagusic acid 28 gave cNDI 37. Hydrazide deprotection quenched by benzaldehyde 30 gave the yellow cNDI propagator 4.

The activated asparagusic acid 28 was prepared by following literature procedures [22-25]. In the first step from bis(hydroxymethyl)malonate 38, simple nucleophilic substitution is coupled with an ester hydrolysis and a debrominative decarboxylation. Another nucleophilic substitution with thioacetate converted bromide 39 into thioester 40. Addition of a second thioacetate gave dithioester 41, which was hydrolyzed with a base. Oxidation of dithiol 42 with molecular oxygen gave asparagusic acid (43), which is the natural product that contributes to the characteristic odor of asparagus. Activation with NHS gave the ester 28, ready for coupling with amines, such as 27 or 36.

Synthesis of stack exchangers

The synthesis of the red cNDIs 5 and 6 for stack exchange was possible in very few steps starting from available synthetic intermediates (Scheme 3). cNDI 5, with one bromo and one alkylamino substituent in the core, was prepared from crude dibromo cNDA 32. Microwave-assisted reaction [15] with amines 14 and 15 gave the mixed cNDI 44 together with the symmetric side products. The obtained mixture of 2,6- and 3,7-regioisomers was not separated throughout the entire synthesis of photosystem 1. Nucleophilic aromatic substitution with isopropylamine for 10 min at room temperature gave the red cNDI 45, which was followed by deprotection with acid to give the target aldehyde 5.

Scheme 3: Synthesis of stack exchangers 5 and 6. Compounds 5, 6, 45 and 47 are mixtures of 2,6- and 3,7-regioisomers.

Scheme 3: Synthesis of stack exchangers 5 and 6. Compounds 5, 6, 45 and 47 are mixtures of 2,6- and 3,7-regio...

The more pinkish cNDI 6 was synthesized from the cNTE 34 following the procedure developed for cNDI 5. Diimide formation with amines 14 and 15 followed by core substitution of the mixed cNDI 46 and deprotection of the red cNDI 47 gave the desired aldehyde 6.

Self-organizing surface-initiated polymerization

With the five building blocks 2–6 in hand, the solid-phase synthesis of photosystem 1 on ITO surfaces could be launched. ITO was first cleaned with RCA solution, that is, a boiling 5:1:1 mixture of water, 24% NH4OH and 30% H2O2, and then rinsed with bidistilled water and EtOH, and dried. Then the ITO was immersed in a 3 mM solution of initiator 2 in DMSO for 2 days. The formation of monolayers of 48 on ITO electrodes was followed by the inhibition of potassium ferricyanide reduction in solution, and by absorption spectroscopy (Scheme 4). The obtained monolayers of 48 were annealed for 1 h in the oven at 120 °C. These conditions are known to improve the covalent bonding between phosphonic acids and the ITO substrate [26].

Scheme 4: Synthesis of photosystem 1, self-organizing surface-initiated polymerization (SOSIP). R1 = SH (50) or oxidized derivative (51), grey surface = ITO. Dotted lines from diphosphonate groups indicate the bonds to the ITO surface. The polymer structures are generalized and idealized structures, which are consistent with the experimental results. They will naturally contain defects.

Scheme 4: Synthesis of photosystem 1, self-organizing surface-initiated polymerization (SOSIP). R1 = SH (50) ...

The disulfide protecting groups on the surface of monolayer 48 were removed with DTT to afford free thiols on the surface of monolayer 49. For SOSIP [18,19], the concentration of propagators had to be optimized to a critical SOSIP concentration, cSOSIP. Below cSOSIP, ring-opening disulfide-exchange polymerization [27] does not occur, whereas above cSOSIP, the polymerization occurs everywhere, not only on the surface but also in solution. To determine cSOSIP, ITO plates with and without activated initiators were incubated together in the same solution of propagators. The amount of polymers either grown from the ITO surface or deposited on the ITO surface by precipitation during polymerization in solution was determined by absorption spectroscopy. Plots of the absorption of the electrode as a function of the concentration of the propagator in solution revealed both cSOSIP, the critical concentration needed for SOSIP, and cSOL, the critical concentration needed for polymerization in solution. Operational SOSIP was demonstrated with cSOSIP < cSOL, and failure of SOSIP with cSOSIP = cSOL. Both cSOSIP and cSOL depended strongly on the conditions, i.e., the concentration and nature of the base catalyst, the nature of initiator and propagator, the temperature, the presence of oxygen in the solution and, most importantly, the composition of the solvent mixture used.

For propagator 3, cSOSIP = 3.5 mM was found in a 1:1 mixture of chloroform and methanol with 100 mM DIPEA as a base catalyst. Incubation of monolayer 49 in this solution gave SOSIP architecture 50. To add the yellow stacks in photosystem 1, photosystem 50 was incubated with propagator 4 at cSOSIP = 7 mM in chloroform/methanol (1:1) with 100 mM DIPEA. The obtained oriented diblock disulfide polymers 51 were characterized by the absorption of colorless NDIs at 385 nm and the absorption of yellow cNDIs at 470 nm. Assuming regular growth, these absorptions provided a meaningful approximation of the average composition n and m of the poly(disulfide) [27].

Stack exchange

Stack exchange within the resulting SOSIP photosystem 51 was initiated with excess hydroxylamine (Scheme 5). The chemoorthogonality of disulfide and hydrazone exchange has been demonstrated previously by several groups [28-31]. Benzaldehyde removal as oxime was followed by HPLC. The hydrazide-rich pores produced in the resulting architecture 52 were first filled by reversible covalent capture of the red cNDI aldehyde 5.

Scheme 5: Synthesis of photosystem 1, stack exchange. R1 = SH or oxidized derivative, R1 = CH2CHCH2. 5 and 6 are mixtures of 2,6- and 3,7-regioisomers.

Scheme 5: Synthesis of photosystem 1, stack exchange. R1 = SH or oxidized derivative, R1 = CH2CHCH2. 5 and 6 ...

Stack exchange was easily detectable by comparison of the respective maxima in the absorption spectra. Exchange of the benzaldehyde hydrazones in photosystem 51 with NDIs occurred with an excellent 75–95% yield. Moreover, the yield of stack exchange was nearly independent of the thickness of the photosystem. Control experiments revealed that in the case of initiators without extra NDI templates, the yield drops to 40% for thin photosystems and further decreases with increasing thickness to an irrelevant 25%. This significant difference demonstrates the central importance of templated synthesis for successful stack exchange.

To engineer antiparallel gradients into the red stack of photosystem 53, partial stack exchange was envisioned. A part of the red cNDI stack, l, was removed by brief treatment with hydroxylamine. The produced, shallower holes in photosystem 54 were filled with cNDI aldehyde 6. The desired photosystem 1 with antiparallel redox gradients in coaxial hole- and electron-transporting channels was obtained.

Graphical summary of complex transformations

Both SOSIP and post-SOSIP stack exchange can be quite complicated to follow in complete molecular structures (Scheme 4 and Scheme 5). We thus summarize both processes in schematic form (Scheme 6). To recapitulate briefly from this perspective, we repeat that the solid-phase synthesis begins with the deposition of initiator 2 on ITO. Activation of monolayer 48 with DTT produces monolayer 49 with free thiols on the surface. Recognition of propagators 3 on the surface of 49 places the strained disulfides of asparagusic acid right on top of the activated thiolates on the surface. Covalent capture by ring-opening disulfide exchange generates new thiolates on the surface of the growing photosystem 55 for continuing SOSIP. The obtained ladderphane 50 is then treated with propagator 4. Ring-opening disulfide exchange SOSIP via intermediates 56 leads to photosystem 51 with a two-component redox gradient in the π-stack.

![[1860-5397-8-102-i6]](/bjoc/content/inline/1860-5397-8-102-i6.png?scale=2.0&max-width=1024&background=FFFFFF)

Scheme 6: Schematic overview over SOSIP and stack exchange.

Scheme 6: Schematic overview over SOSIP and stack exchange.

Post-SOSIP stack exchange is then initiated by benzaldehyde removal as oxime 57. The giant pores drilled into photosystem 52 are first filled completely with red cNDI 5. Subsequently, the partial removal of the new stack in photosystem 53 as oxime 58 and covalent capture of 6 in the more shallow pores in photosystem 54 affords the desired double-gradient photosystem 1.

Conclusion

The objective of this brief highlight was to exemplify the synthetic efforts that are often hidden behind short papers on functional systems. Quite extensive multistep synthesis has been covered, followed by innovative surface-initiated polymerization and chemoorthogonal dynamic covalent chemistry. The excellent properties obtained confirm that significant synthetic efforts to build more sophisticated functional systems can be justified and rewarding. In this research, multistep organic synthesis is the means rather than the end. Therefore, the main difference from research dedicated to synthetic methodology is that the individual steps often remain unoptimized as long as the level reached is sufficient to produce large enough amounts of the target molecule without extensive effort and cost. However, the quality, timeliness and beauty of the transformations employed are the same, as is the pleasure of occasional contributions to improve or innovate in the field of organic synthesis.

References

-

Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 18542–18545. doi:10.1021/ja207587x

Return to citation in text: [1] [2] [3] -

Bhosale, R.; Míšek, J.; Sakai, N.; Matile, S. Chem. Soc. Rev. 2010, 39, 138–149. doi:10.1039/b906115k

Return to citation in text: [1] -

Sakai, N.; Bhosale, R.; Emery, D.; Mareda, J.; Matile, S. J. Am. Chem. Soc. 2010, 132, 6923–6925. doi:10.1021/ja101944r

Return to citation in text: [1] -

Sakai, N.; Mareda, J.; Vauthey, E.; Matile, S. Chem. Commun. 2010, 46, 4225–4237. doi:10.1039/c0cc00078g

Return to citation in text: [1] -

Bhosale, S. V.; Jani, C. H.; Lalander, C. H.; Langford, S. J.; Nerush, I.; Shapter, J. G.; Villamaina, D.; Vauthey, E. Chem. Commun. 2011, 47, 8226–8228. doi:10.1039/c1cc11318f

Return to citation in text: [1] -

Hu, Y.; Gao, X.; Di, C.; Yang, X.; Zhang, F.; Liu, Y.; Li, H.; Zhu, D. Chem. Mater. 2011, 23, 1204–1215. doi:10.1021/cm102850j

Return to citation in text: [1] -

Gabutti, S.; Knutzen, M.; Neuburger, M.; Schull, G.; Berndt, R.; Mayor, M. Chem. Commun. 2008, 2370–2372. doi:10.1039/b719796a

Return to citation in text: [1] -

Jones, B. A.; Facchetti, A.; Wasielewski, M. R.; Marks, T. J. J. Am. Chem. Soc. 2007, 129, 15259–15278. doi:10.1021/ja075242e

Return to citation in text: [1] -

Molla, M. R.; Das, A.; Ghosh, S. Chem.–Eur. J. 2010, 16, 10084–10093. doi:10.1002/chem.201000596

Return to citation in text: [1] -

Nakamura, M.; Okaue, T.; Takada, T.; Yamana, K. Chem.–Eur. J. 2012, 18, 196–201. doi:10.1002/chem.201102216

Return to citation in text: [1] -

Guha, S.; Goodson, F. S.; Roy, S.; Corson, L. J.; Gravenmier, C. A.; Saha, S. J. Am. Chem. Soc. 2011, 133, 15256–15259. doi:10.1021/ja2055726

Return to citation in text: [1] -

Chaignon, F.; Falkenström, M.; Karlsson, S.; Blart, E.; Odobel, F.; Hammarström, L. Chem. Commun. 2007, 64–66. doi:10.1039/b615085c

Return to citation in text: [1] -

Alvey, P. M.; Reczek, J. J.; Lynch, V.; Iverson, B. L. J. Org. Chem. 2010, 75, 7682–7690. doi:10.1021/jo101498b

Return to citation in text: [1] -

Shukla, D.; Nelson, S. F.; Freeman, D. C.; Rajeswaran, M.; Ahearn, W. G.; Meyer, D. M.; Carey, J. T. Chem. Mater. 2008, 20, 7486–7491. doi:10.1021/cm802071w

Return to citation in text: [1] -

Pengo, P.; Pantos, G. D.; Otto, S.; Sanders, J. K. M. J. Org. Chem. 2006, 71, 7063–7066. doi:10.1021/jo061195h

Return to citation in text: [1] [2] [3] [4] -

Kishore, R. S. K.; Kel, O.; Banerji, N.; Emery, D.; Bollot, G.; Mareda, J.; Gomez-Casado, A.; Jonkheijm, P.; Huskens, J.; Maroni, P.; Borkovec, M.; Vauthey, E.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2009, 131, 11106–11116. doi:10.1021/ja9030648

Return to citation in text: [1] [2] [3] -

Thalacker, C.; Röger, C.; Würthner, F. J. Org. Chem. 2006, 71, 8098–8105. doi:10.1021/jo0612269

Return to citation in text: [1] -

Sakai, N.; Lista, M.; Kel, O.; Sakurai, S.; Emery, D.; Mareda, J.; Vauthey, E.; Matile, S. J. Am. Chem. Soc. 2011, 133, 15224–15227. doi:10.1021/ja203792n

Return to citation in text: [1] [2] -

Lista, M.; Areephong, J.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 15228–15231. doi:10.1021/ja204020p

Return to citation in text: [1] [2] -

Page, P. C. B.; McKenzie, M. J.; Gallagher, J. A. J. Org. Chem. 2001, 66, 3704–3708. doi:10.1021/jo001489h

Return to citation in text: [1] [2] -

Page, P. C. B.; McKenzie, M. J.; Gallagher, J. A. Synth. Commun. 2002, 32, 211–218. doi:10.1081/SCC-120002004

Return to citation in text: [1] [2] -

Singh, R.; Whitesides, G. M. J. Am. Chem. Soc. 1990, 112, 1190–1197. doi:10.1021/ja00159a046

Return to citation in text: [1] -

Danehy, J. P.; Elia, V. J. J. Org. Chem. 1972, 37, 369–373. doi:10.1021/jo00968a008

Return to citation in text: [1] -

Schotte, L.; Ström, H. Acta Chem. Scand. 1956, 10, 687–688. doi:10.3891/acta.chem.scand.10-0687

Return to citation in text: [1] -

Unger, F. M.; Liehl, E. 1,2-dithiolan derivatives, process for their production pharmaceutical compositions containing them and their use. GB Patent Application GB2148296A, May 30, 1985.

Return to citation in text: [1] -

Paniagua, S. A.; Hotchkiss, P. J.; Jones, S. C.; Marder, S. R.; Mudalige, A.; Marrikar, F. S.; Pemberton, J. E.; Armstrong, N. R. J. Phys. Chem. C 2008, 112, 7809–7817. doi:10.1021/jp710893k

Return to citation in text: [1] -

Bang, E.-K.; Lista, M.; Sforazzini, G.; Sakai, N.; Matile, S. Chem. Sci. 2012, 3, 1752–1763. doi:10.1039/C2SC20098H

Return to citation in text: [1] [2] -

Rodriguez-Docampo, Z.; Otto, S. Chem. Commun. 2008, 5301–5303. doi:10.1039/B808725C

Return to citation in text: [1] -

von Delius, M.; Geertsema, E. M.; Leigh, D. A. Nat. Chem. 2010, 2, 96–101. doi:10.1038/nchem.481

Return to citation in text: [1] -

Corbett, P. T.; Leclaire, J.; Vial, L.; West, K. R.; Wietor, J.-L.; Sanders, J. K. M.; Otto, S. Chem. Rev. 2006, 106, 3652–3711. doi:10.1021/cr020452p

Return to citation in text: [1] -

Skene, W. G.; Lehn, J.-M. P. Proc. Natl. Acad. Sci. U. S. A. 2004, 101, 8270–8275. doi:10.1073/pnas.0401885101

Return to citation in text: [1]

| 27. | Bang, E.-K.; Lista, M.; Sforazzini, G.; Sakai, N.; Matile, S. Chem. Sci. 2012, 3, 1752–1763. doi:10.1039/C2SC20098H |

| 28. | Rodriguez-Docampo, Z.; Otto, S. Chem. Commun. 2008, 5301–5303. doi:10.1039/B808725C |

| 29. | von Delius, M.; Geertsema, E. M.; Leigh, D. A. Nat. Chem. 2010, 2, 96–101. doi:10.1038/nchem.481 |

| 30. | Corbett, P. T.; Leclaire, J.; Vial, L.; West, K. R.; Wietor, J.-L.; Sanders, J. K. M.; Otto, S. Chem. Rev. 2006, 106, 3652–3711. doi:10.1021/cr020452p |

| 31. | Skene, W. G.; Lehn, J.-M. P. Proc. Natl. Acad. Sci. U. S. A. 2004, 101, 8270–8275. doi:10.1073/pnas.0401885101 |

| 1. | Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 18542–18545. doi:10.1021/ja207587x |

| 4. | Sakai, N.; Mareda, J.; Vauthey, E.; Matile, S. Chem. Commun. 2010, 46, 4225–4237. doi:10.1039/c0cc00078g |

| 5. | Bhosale, S. V.; Jani, C. H.; Lalander, C. H.; Langford, S. J.; Nerush, I.; Shapter, J. G.; Villamaina, D.; Vauthey, E. Chem. Commun. 2011, 47, 8226–8228. doi:10.1039/c1cc11318f |

| 6. | Hu, Y.; Gao, X.; Di, C.; Yang, X.; Zhang, F.; Liu, Y.; Li, H.; Zhu, D. Chem. Mater. 2011, 23, 1204–1215. doi:10.1021/cm102850j |

| 7. | Gabutti, S.; Knutzen, M.; Neuburger, M.; Schull, G.; Berndt, R.; Mayor, M. Chem. Commun. 2008, 2370–2372. doi:10.1039/b719796a |

| 8. | Jones, B. A.; Facchetti, A.; Wasielewski, M. R.; Marks, T. J. J. Am. Chem. Soc. 2007, 129, 15259–15278. doi:10.1021/ja075242e |

| 9. | Molla, M. R.; Das, A.; Ghosh, S. Chem.–Eur. J. 2010, 16, 10084–10093. doi:10.1002/chem.201000596 |

| 10. | Nakamura, M.; Okaue, T.; Takada, T.; Yamana, K. Chem.–Eur. J. 2012, 18, 196–201. doi:10.1002/chem.201102216 |

| 11. | Guha, S.; Goodson, F. S.; Roy, S.; Corson, L. J.; Gravenmier, C. A.; Saha, S. J. Am. Chem. Soc. 2011, 133, 15256–15259. doi:10.1021/ja2055726 |

| 12. | Chaignon, F.; Falkenström, M.; Karlsson, S.; Blart, E.; Odobel, F.; Hammarström, L. Chem. Commun. 2007, 64–66. doi:10.1039/b615085c |

| 13. | Alvey, P. M.; Reczek, J. J.; Lynch, V.; Iverson, B. L. J. Org. Chem. 2010, 75, 7682–7690. doi:10.1021/jo101498b |

| 14. | Shukla, D.; Nelson, S. F.; Freeman, D. C.; Rajeswaran, M.; Ahearn, W. G.; Meyer, D. M.; Carey, J. T. Chem. Mater. 2008, 20, 7486–7491. doi:10.1021/cm802071w |

| 15. | Pengo, P.; Pantos, G. D.; Otto, S.; Sanders, J. K. M. J. Org. Chem. 2006, 71, 7063–7066. doi:10.1021/jo061195h |

| 16. | Kishore, R. S. K.; Kel, O.; Banerji, N.; Emery, D.; Bollot, G.; Mareda, J.; Gomez-Casado, A.; Jonkheijm, P.; Huskens, J.; Maroni, P.; Borkovec, M.; Vauthey, E.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2009, 131, 11106–11116. doi:10.1021/ja9030648 |

| 17. | Thalacker, C.; Röger, C.; Würthner, F. J. Org. Chem. 2006, 71, 8098–8105. doi:10.1021/jo0612269 |

| 18. | Sakai, N.; Lista, M.; Kel, O.; Sakurai, S.; Emery, D.; Mareda, J.; Vauthey, E.; Matile, S. J. Am. Chem. Soc. 2011, 133, 15224–15227. doi:10.1021/ja203792n |

| 19. | Lista, M.; Areephong, J.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 15228–15231. doi:10.1021/ja204020p |

| 18. | Sakai, N.; Lista, M.; Kel, O.; Sakurai, S.; Emery, D.; Mareda, J.; Vauthey, E.; Matile, S. J. Am. Chem. Soc. 2011, 133, 15224–15227. doi:10.1021/ja203792n |

| 19. | Lista, M.; Areephong, J.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 15228–15231. doi:10.1021/ja204020p |

| 1. | Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 18542–18545. doi:10.1021/ja207587x |

| 27. | Bang, E.-K.; Lista, M.; Sforazzini, G.; Sakai, N.; Matile, S. Chem. Sci. 2012, 3, 1752–1763. doi:10.1039/C2SC20098H |

| 1. | Sakai, N.; Matile, S. J. Am. Chem. Soc. 2011, 133, 18542–18545. doi:10.1021/ja207587x |

| 15. | Pengo, P.; Pantos, G. D.; Otto, S.; Sanders, J. K. M. J. Org. Chem. 2006, 71, 7063–7066. doi:10.1021/jo061195h |

| 2. | Bhosale, R.; Míšek, J.; Sakai, N.; Matile, S. Chem. Soc. Rev. 2010, 39, 138–149. doi:10.1039/b906115k |

| 3. | Sakai, N.; Bhosale, R.; Emery, D.; Mareda, J.; Matile, S. J. Am. Chem. Soc. 2010, 132, 6923–6925. doi:10.1021/ja101944r |

| 26. | Paniagua, S. A.; Hotchkiss, P. J.; Jones, S. C.; Marder, S. R.; Mudalige, A.; Marrikar, F. S.; Pemberton, J. E.; Armstrong, N. R. J. Phys. Chem. C 2008, 112, 7809–7817. doi:10.1021/jp710893k |

| 15. | Pengo, P.; Pantos, G. D.; Otto, S.; Sanders, J. K. M. J. Org. Chem. 2006, 71, 7063–7066. doi:10.1021/jo061195h |

| 16. | Kishore, R. S. K.; Kel, O.; Banerji, N.; Emery, D.; Bollot, G.; Mareda, J.; Gomez-Casado, A.; Jonkheijm, P.; Huskens, J.; Maroni, P.; Borkovec, M.; Vauthey, E.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2009, 131, 11106–11116. doi:10.1021/ja9030648 |

| 15. | Pengo, P.; Pantos, G. D.; Otto, S.; Sanders, J. K. M. J. Org. Chem. 2006, 71, 7063–7066. doi:10.1021/jo061195h |

| 22. | Singh, R.; Whitesides, G. M. J. Am. Chem. Soc. 1990, 112, 1190–1197. doi:10.1021/ja00159a046 |

| 23. | Danehy, J. P.; Elia, V. J. J. Org. Chem. 1972, 37, 369–373. doi:10.1021/jo00968a008 |

| 24. | Schotte, L.; Ström, H. Acta Chem. Scand. 1956, 10, 687–688. doi:10.3891/acta.chem.scand.10-0687 |

| 25. | Unger, F. M.; Liehl, E. 1,2-dithiolan derivatives, process for their production pharmaceutical compositions containing them and their use. GB Patent Application GB2148296A, May 30, 1985. |

| 20. | Page, P. C. B.; McKenzie, M. J.; Gallagher, J. A. J. Org. Chem. 2001, 66, 3704–3708. doi:10.1021/jo001489h |

| 21. | Page, P. C. B.; McKenzie, M. J.; Gallagher, J. A. Synth. Commun. 2002, 32, 211–218. doi:10.1081/SCC-120002004 |

| 20. | Page, P. C. B.; McKenzie, M. J.; Gallagher, J. A. J. Org. Chem. 2001, 66, 3704–3708. doi:10.1021/jo001489h |

| 21. | Page, P. C. B.; McKenzie, M. J.; Gallagher, J. A. Synth. Commun. 2002, 32, 211–218. doi:10.1081/SCC-120002004 |

| 16. | Kishore, R. S. K.; Kel, O.; Banerji, N.; Emery, D.; Bollot, G.; Mareda, J.; Gomez-Casado, A.; Jonkheijm, P.; Huskens, J.; Maroni, P.; Borkovec, M.; Vauthey, E.; Sakai, N.; Matile, S. J. Am. Chem. Soc. 2009, 131, 11106–11116. doi:10.1021/ja9030648 |

© 2012 Sakai and Matile; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)