Abstract

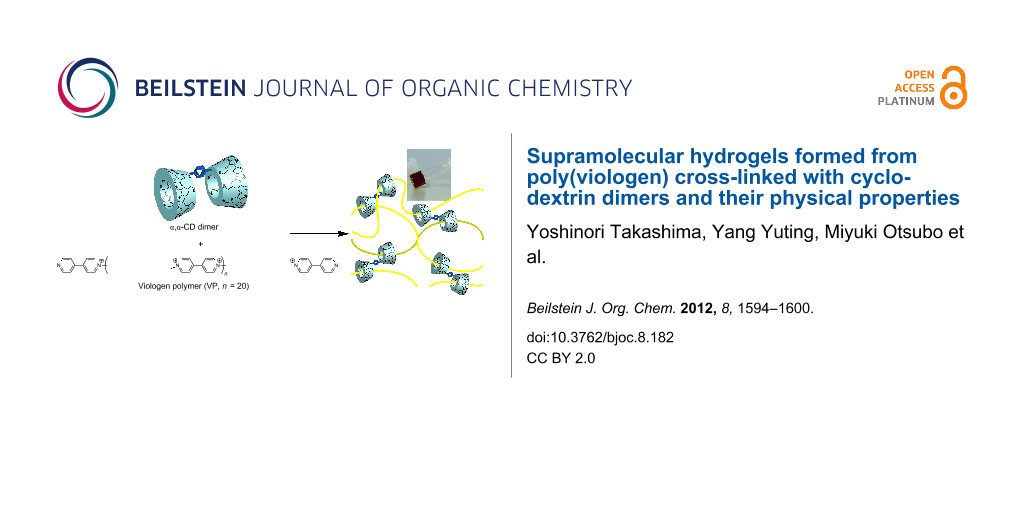

Supramolecular materials with noncovalent bonds have attracted much attention due to their exclusive properties differentiating them from materials formed solely by covalent bonds. Especially interesting are rotor molecules of topological complexes that shuttle along a polymer chain. The shuttling of these molecules should greatly improve the tension strength. Our research employs cyclodextrin (CD) as a host molecule, because CD effectively forms polyrotaxanes with polymers. Herein we report the formation of supramolecular hydrogels with an α-CD dimer (α,α-CD dimer) as a topological linker molecule, and a viologen polymer (VP) as the polymer chain. The supramolecular hydrogel of α,α-CD dimer/VP forms a self-standing gel, which does not relax (G' > G'') in the frequency range 0.01–10 rad·s−1. On the other hand, the supramolecular hydrogel decomposes upon addition of bispyridyl decamethylene (PyC10Py) as a competitive guest. Moreover, the β-CD dimer (β,β-CD dimer) with VP does not form a supramolecular hydrogel, indicating that complexation between the C10 unit of VP and the α-CD unit of the α,α-CD dimer plays an important role in the formation of supramolecular hydrogels.

Graphical Abstract

Introduction

Development of functional soft materials has attracted much attention due to the numerous practical applications [1-3]. Typically, soft materials fall into one of two types of gels: physical gels and chemical gels [4-9]. Recently, topological cross-linked polyrotaxanes have been identified as tertiary gels, which should create a new paradigm in materials science [10]. Polyrotaxanes form topological gels, because the rotor molecules, which act as cross-linkers, slide on the axial polymer chain. In contrast, chemical gels do not exhibit cross-linker slippage.

Previously, there have been some reports of supramolecular complexes with cyclodextrin (CD) dimers. A supramolecular hydrogel, which was constructed by the formation of an inclusion complex between the copolymer with an adamantyl group and CD dimer, showed a lower critical solution temperature (LCST) [11]. Another report indicated that adding selenium or platinum complexes yields supramolecular assemblies of bis(molecular tube)s cross-linked with the β-CD dimer, which form nanofibers [12-15]. Moreover, mechanically linked polyrotaxane with the α-CD and poly(ethylene glycol) (PEG) produces a hydrogel material, which exhibits unique physical properties [10].

Previously, we have prepared a polyrotaxane using α-CD and PEG [16,17]. The α-CD/PEG polyrotaxane forms a hydrogel material in high concentrations [18]. Using polyelectrolytes as threading molecules results in complexation between the polyelectrolyte and α-CD within the range of the 1H NMR time scale due to the slow equilibrium [19,20]. Cationic groups, such as pyridinium and pyridylpyridinium terminal groups, inhibit the decomposition of polyrotaxane and stabilize the complexes between α-CD and cationic alkanediyl compounds [21-23]. Herein, to study the formation of supramolecular hydrogels with the α,α-CD dimer, we chose the viologen polymer (VP), which possesses multiple cations, as the axis molecules. Decamethylene units function as recognition sites of α-CD, and bipyridyls work as electric barriers.

Results and Discussion

Preparation of CD dimers and viologen derivatives

Figure 1 depicts the chemical structures of the cyclodextrin dimers (α,α-CD dimer, α,β-CD dimer, and β,β-CD dimer) and pyridyl derivatives (PyC10Py and viologen polymer (VP)). The α,α-CD and β,β-CD dimers are prepared by reacting the corresponding 6-amino-CDs and terephthalic acid using 4-(4,6-dimethoxy-1,3,5-triazin-2-yl)-4-methylmorpholinium chloride n-hydrate (DMT-MM) as a condensing reagent in DMF. The α,β-CD dimer is prepared by reacting 6-amino-α-CD and 6-O-(4-carboxylphenylamide)-β-CD using DMT-MM in DMF. These CD dimers are purified by preparative reversed-phase chromatography using DIAION HP-20 beads. As described in the experimental section, the reaction of 1,10-dibromodecane with 4,4’-bipyridyl in DMF gives VP, where the number of VP units is 20 and was determined by the ratio of integral values of the end group and the main chain unit in the 1H NMR spectrum.

![[1860-5397-8-182-1]](/bjoc/content/figures/1860-5397-8-182-1.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: Chemical structures of the CD dimer (α,α-CD dimer, α,β-CD dimer, and β,β-CD dimer) and guest derivatives [PyC10Py and viologen polymer (VP)]. Bromonium anions are omitted in guest derivatives.

Figure 1: Chemical structures of the CD dimer (α,α-CD dimer, α,β-CD dimer, and β,β-CD dimer) and guest deriva...

Hydrogelation between the CD dimer and viologen polymer

Mixing the α,α-CD dimer and VP in aqueous solutions at room temperature slightly increases the viscosity of the α,α-CD dimer/VP, but hydrogels are not formed. On the other hand, after heating at 100 °C for 7 h, an aqueous solution of the α,α-CD dimer/VP forms a supramolecular hydrogel containing over 30 mM (VP unit/CD unit 4:1) (Figure 2). The bipyridyl group of VP functions as an electric barrier, which prevents threading and dethreading of the α-CD unit in the α,α-CD dimer onto the decamethylene unit of VP at 30 °C; this observation suggests that the α-CD unit of the α,α-CD dimer cannot exceed the electric barrier at 30 °C, whereas after heating at 100 °C, the α-CD unit exceeds the barrier to form polyrotaxanes.

![[1860-5397-8-182-2]](/bjoc/content/figures/1860-5397-8-182-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: Photographs of hydrogelation with various concentrations of α,α-CD dimer/VP in water. Aqueous solution of α,α-CD dimer/VP forms the hydrogel at concentrations above 30 mM.

Figure 2: Photographs of hydrogelation with various concentrations of α,α-CD dimer/VP in water. Aqueous solut...

To confirm complementarity between the CD dimer and VP, we then investigated the formation of supramolecular hydrogels of VP with the α,β-CD dimer and the β,β-CD dimer. For each sample, the CD concentration was adjusted to 120 mM (VP unit/CD unit 4:1). Even with a dimer/VP concentration greater than 60 mM, the α,β-CD dimer/VP and β,β-CD dimer/VP do not form supramolecular hydrogels. These results indicate that complexation between the C10 unit of VP and the α-CD unit of the α,α-CD dimer is important for the formation of cross-links between VPs (Figure 3). The cavity size of β-CD is too large to allow formation of a stable cross-linked polyrotaxane complex. The α,β-CD dimer and β,β-CD dimer do not function as crosslinking molecules between VP and β-CD. Actually, the association constant of α-CD with decamethylene is much higher than that of β-CD with decamethylene [24]. Consequently, the association constant plays an important role in gel formation.

![[1860-5397-8-182-3]](/bjoc/content/figures/1860-5397-8-182-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: Hydrogelation of VP with various CD derivatives (VP unit/CD 4:1) at 25 °C. (a) Concentrations of CDs are 120 mM. (b) Proposed structure of the α,α-CD dimer/VP supramolecular hydrogel.

Figure 3: Hydrogelation of VP with various CD derivatives (VP unit/CD 4:1) at 25 °C. (a) Concentrations of CD...

To confirm a supramolecular hydrogel formed by crosslinking VP with the α,α-CD dimer, we added PyC10Py as a competitive guest to the supramolecular hydrogel of the α,α-CD dimer/VP. After adding PyC10Py (PyC10Py/VP unit/α,α-CD dimer 8:8:1) and heating at 100 °C, the supramolecular hydrogel of the α,α-CD dimer/VP changes to the sol even at a high concentration ([α,α-CD dimer] = 60 mM), because the α-CD unit of the α,α-CD dimer forms an inclusion complex with PyC10Py. This inclusion-complex formation causes the cross-links between the α,α-CD dimer and VP to decompose.

1H NMR study of complexation of the α,α-CD dimer/VP

To observe the competitive effect of PyC10Py, we conducted 1H NMR studies on complexation between α-CD/VP and a competitive experiment using PyC10Py. Figure 4 shows 1H NMR spectra of VP/PyC10Py, VP/α-CD, and VP/α-CD/PyC10Py. Addition of α-CD causes peak splitting of the decamethylene and pyridyl protons of VP (VP unit/α-CD 1:2), indicating the formation of a polyrotaxane VP/α-CD complex. The association–dissociation equilibrium between VP and α-CD is slow on the NMR time scale. On the other hand, upon addition of PyC10Py to the VP/α-CD complex (VP unit/α-CD/PyC10Py 1:2:8), the splitting peaks of the VP/α-CD complex disappear, and then signals of PyC10Py split due to complexation between PyC10Py and α-CD (Figure 4c). These results indicate that the excess PyC10Py disturbs complexation of α-CD and VP. The sol state of the α,α-CD dimer/VP in the presence of PyC10Py is attributed to the dissociation of VP and the α,α-CD dimer, suggesting that complexation between VP and the α-CD units is necessary to form the gel.

![[1860-5397-8-182-4]](/bjoc/content/figures/1860-5397-8-182-4.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 4: 500 MHz 1H NMR spectra of VP (VP unit 2 mM) with α-CD and PyC10Py (VP unit/CD/PyC10Py 1:2:8) in D2O at 30 oC: (a) VP and PyC10Py, (b) VP and α-CD, and (c) VP, PyC10Py, and α-CD.

Figure 4: 500 MHz 1H NMR spectra of VP (VP unit 2 mM) with α-CD and PyC10Py (VP unit/CD/PyC10Py 1:2:8) in D2O...

Viscoelastic property of the α,α-CD dimer/VP hydrogel

Figure 5 shows the storage elastic modulus (G') and loss elastic modulus (G'') for an α,α-CD dimer/VP hydrogel (60 mM) at 20 °C. The master curve of the hydrogel is similar to the Voigt Model. G'' relaxes as the frequency increases. However, the hydrogel does not relax (G' > G'') in the frequency range 0.01–10 rad·s−1, indicating a self-standing gel. This behavior are similar to chemically cross-linked gels even though the α,α-CD dimer/VP hydrogel is topologically cross-linked between VPs with the α,α-CD dimer. This result confirms that complexation of VP and the α,α-CD dimer is stable and responsible for the stability of the hydrogel.

![[1860-5397-8-182-5]](/bjoc/content/figures/1860-5397-8-182-5.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 5: G' and G'' of the α,α-CD dimer/VP hydrogel as a function of frequency (ω). Applied shear strain amplitude is 1%.

Figure 5: G' and G'' of the α,α-CD dimer/VP hydrogel as a function of frequency (ω). Applied shear strain amp...

Conclusion

Mixing VP and the α,α-CD dimer creates a hydrogel, which is expected to realize supramolecular materials with a high tensile strength and self-healing abilities. The complementarity between α-CD and the decamethylene units plays an important role in the formation of supramolecular hydrogels composed of α,α-CD dimer/VP. VP has an electric barrier between the decamethylene units, which is a unique feature of this supramolecular hydrogel. The electric barrier prevents dethreading of α-CD from VP, yielding a self-standing supramolecular hydrogel. We will electrochemically control the elasticity of the α,α-CD dimer/VP hydrogel.

Experimental

Preparation of α,α-CD dimer

![[Graphic 1]](/bjoc/content/inline/1860-5397-8-182-i1.png?max-width=637&scale=1.3000021)

6-NH2-α-CD (120 mg, 0.12 mmol) and terephthalic acid (8 mg, 0.50 mmol) were dissolved in dried DMF (20 mL). DMT-MM (34 mg, 0.12 mmol) was added and the mixture was stirred at rt for 4 days. After evaporation of the solvent, the residue was dissolved in water (10 mL) and poured into acetone (100 mL). The product was collected and purified by reversed-phase chromatography (elution: water–acetonitrile) to give α,α-CD dimer as a white solid in 22% yield. 1H NMR (DMSO-d6, 500 MHz) δ 8.36 (t, 2H, -NH), 7.88 (s, 4H, Ph), 5.59–5.40 (m, 24H, O(2,3)H of α-CD), 4.97–4.78 (m, 12H, C(1)H of α-CD), 4.55–4.41 (m, 10H, O(6)H of α-CD), 3.84–3.48 (m, C(3,6,5,3,4)H of α-CD); MALDI–TOF m/z: 2095 [M + Na]+.

Preparation of α,β-CD dimer

a) Methyl terephthalate-β-CD

![[Graphic 2]](/bjoc/content/inline/1860-5397-8-182-i2.png?max-width=637&scale=1.18182)

To a solution of 6-NH2-β-CD (566 mg, 0.50 mmol) in dried DMF (7 mL) was added methyl terephthalate succinimidyl ester (137.6 mg, 0.50 mmol). After stirring for 2 days at rt, the solution was poured into acetone (100 mL) to give methyl terephthalate-β-CD as a yellow solid in 43% yield. 1H NMR (DMSO-d6, 500 MHz) δ 8.46 (t, 1H, -NH), 8.00 (d, 2H, Ph), 7.95 (s, 3H, -CH3), 7.94 (d, 2H, Ph), 5.83–5.59 (m, 14H, O(2,3)H of β-CD), 4.95–4.79 (m, 7H, C(1)H of β-CD), 4.45–4.32 (m, 6H, O(6)H of β-CD), 3.74–3.51 (m, C(3,6,5,3,4)H of α-CD); TLC: Rf 0.22 (n-butanol/ethanol/water 5:4:3).

b) Terephthalic acid-β-CD

![[Graphic 3]](/bjoc/content/inline/1860-5397-8-182-i3.png?max-width=637&scale=1.1227291)

To a solution of methyl terephthalate-β-CD (605 mg, 0.47 mmol) in water (120 mL) was added NaOH (0.1 M, 7 mL). After stirring for 12 hours at rt, the solution was concentrated and purified by DIAION HP-20 column. The column was flushed with water (500 mL) and then eluted with water/methanol 80:20 (v/v). The fraction was concentrated to give terephthalic acid-β-CD as a yellow solid in 70% yield. 1H NMR (DMSO-d6, 500 MHz) δ 8.39 (t, 1H, -NH), 7.98 (d, 2H, Ph), 7.90 (d, 2H, Ph), 5.83–5.59 (m, 14H, O(2,3)H of β-CD), 4.95–4.79 (m, 7H, C(1)H of β-CD), 4.45–4.32 (m, 6H, O(6)H of β-CD), 3.74–3.51 (m, C(3,6,5,3,4)H of α-CD); TLC: Rf 0.32 (n-butanol/ethanol/water 5:4:3).

c) α,β-CD dimer

![[Graphic 4]](/bjoc/content/inline/1860-5397-8-182-i4.png?max-width=637&scale=1.536366)

The synthetic procedure was the same as α,α-CD dimer, using terephthalic acid-β-CD (65 mg, 50 μmol), 6-NH2-α-CD (59 mg, 60 μmol), DMT-MM (17 mg, 60 μmol), dried DMF (8 mL) to give α,β-CD dimer in 36% yield as a white solid. 1H NMR (DMSO-d6, 500 MHz) δ 8.32, 8.27 (m, 2H, -NH), 7.89 (s, 4H, Ph), 5.80–5.44 (m, 26H, O(2,3)H of CDs), 4.97–4.78 (m, 13H, C(1)H of CDs), 4.53–4.35 (m, 11H, O(6)H of CDs), 3.86–3.37 (m, C(3,6,5,3,4)H of α-CD); TLC: Rf 0.04 (n-butanol/ethanol/water 5:4:3); MALDI–TOF m/z: 2259 [M + Na]+.

Preparation of β,β-dimer

β,β-Dimer was prepared according to our previous report [25].

Preparation of viologen polymer (VP)

1,10-Dibromodecane (7.3 g, 24 mmol) was added to a solution of 4,4’-bipyridyl (4 g, 24 mmol) in DMSO (40 mL). After being stirred at 100 °C for 2 d, the solution became turbid. The precipitate was collected and washed with acetone three times. The product was purified by dialysis for 4 d to give VP in 20% yield as a brown solid. 1H NMR (D2O, 500 MHz) δ 9.25 (m, 92H, 2-position of bipyridyl in the middle of the axle), 9.14 (m, 4H, 2-position of bipyridyl at the end of the axle near the decamethylene part), 8.94 (m, 4H, 2-position of bipyridyl at the end of the axle apart from the decamethylene part), 8.69 (m, 92H, 3-position of bipyridyl in the middle of the axle), 8.58 (m, 4H, 3-position of bipyridyl at the end of the axle near the decamethylene part), 8.18 (m, 4H, 3-position of bipyridyl at the end of the axle apart from the decamethylene part), 4.85 (m, 96H, α methylene in decamethylene), 2.21 (m, 96H, β methylene in decamethylene ), 1.72–1.30 (m, 288H, χ, δ, ε methylene in decamethylene).

Preparation of [Py-(CH2)10-Py]2+·2Br− (PyC10Py)

Pyridine (158 mg, 2.0 mmol) and 1,10-dibromodecane (315 mg, 0.80 mmol) were dissolved in acetone and heated under reflux for 3 d. After evaporation of the solvent, the residue was dissolved in methanol (20 mL) and poured into diethyl ether (200 mL). The product was collected by centrifugation to give PyC10Py in 91% yield as a brown solid. 1H NMR (D2O, 500 MHz) δ 8.90 (d, J = 6.6 Hz, 4H, 2-position of pyridine), 8.62 (t, J = 8.2 Hz, 2H, 4-positon of pyridine), 8.14 (t, J = 7.7 Hz, 4H, 3-positon of pyridine), 4.67 (t, J = 7.3 Hz, 4H, α methylene in decamethylene), 2.08 (m, 4H, β methylene in decamethylene), 1.42–1.30 (m, 12H, χ, δ, ε methylene in decamethylene).

Rheological measurements

Dynamic viscoelasticity were measured by using an Anton Paar MCR301 rheometer at a strain of 0.1%. The storage elastic modulus (G') and loss elastic modulus (G'') were measured at 20 °C. The sample concentration was adjusted to 1.0 wt %.

Supporting Information

| Supporting Information File 1: Additional information and 1H NMR spectra of all new compounds. | ||

| Format: PDF | Size: 438.1 KB | Download |

References

-

Gandhi, M. V.; Thompson, B. S. Smart Materials and Structures; Chapman & Hall: London, 1992.

Return to citation in text: [1] -

Urban, M. W., Ed. Handbook of Stimuli-Responsive Materials; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2011.

Return to citation in text: [1] -

Minko, S., Ed. Responsive Polymer Materials: Design and Applications; Blackwell Pub.: Ames, IA, USA, 2006.

Return to citation in text: [1] -

Beaty, C. E.; Saltzman, W. M. J. Controlled Release 1993, 24, 15–23. doi:10.1016/0168-3659(93)90165-2

Return to citation in text: [1] -

Kim, S.; Healy, K. E. Biomacromolecules 2003, 4, 1214–1223. doi:10.1021/bm0340467

Return to citation in text: [1] -

Mahoney, M. J.; Anseth, K. S. Biomaterials 2006, 27, 2265–2274. doi:10.1016/j.biomaterials.2005.11.007

Return to citation in text: [1] -

Petka, W. A.; Harden, J. L.; McGrath, K. P.; Wirtz, D.; Tirrell, D. A. Science 1998, 281, 389–392. doi:10.1126/science.281.5375.389

Return to citation in text: [1] -

Shen, W.; Lammertink, R. G. H.; Sakata, J. K.; Kornfield, J. A.; Tirrell, D. A. Macromolecules 2005, 38, 3909–3916. doi:10.1021/ma048348s

Return to citation in text: [1] -

Hennink, W. E.; van Nostrum, C. F. Adv. Drug Delivery Rev. 2002, 54, 13–36. doi:10.1016/S0169-409X(01)00240-X

Return to citation in text: [1] -

Okumura, Y.; Ito, K. Adv. Mater. 2001, 13, 485–487. doi:10.1002/1521-4095(200104)13:7<485::AID-ADMA485>3.0.CO;2-T

Return to citation in text: [1] [2] -

Kretschmann, O.; Choi, S. W.; Miyauchi, M.; Tomatsu, I.; Harada, A.; Ritter, H. Angew. Chem., Int. Ed. 2006, 45, 4361–4365. doi:10.1002/anie.200504539

Return to citation in text: [1] -

Liu, Y.; You, C.-C.; Zhang, H.-Y.; Kang, S.-Z.; Zhu, C.-F.; Wang, C. Nano Lett. 2001, 1, 613–616. doi:10.1021/nl015550p

Return to citation in text: [1] -

Liu, Y.; Li; Fan, Z.; Zhang, H.-Y.; Wu, X.; Guan, X.-D.; Liu, S.-X. Nano Lett. 2002, 2, 257–261. doi:10.1021/nl015670x

Return to citation in text: [1] -

Liu, Y.; Li; Zhang, H.-Y.; Zhao, Y.-L.; Wu, X. Macromolecules 2002, 35, 9934–9938. doi:10.1021/ma025541i

Return to citation in text: [1] -

Liu, Y.; Song, Y.; Wang, H.; Zhang, H.-Y.; Li, X.-Q. Macromolecules 2004, 37, 6370–6375. doi:10.1021/ma049929k

Return to citation in text: [1] -

Harada, A.; Kamachi, M. Macromolecules 1990, 23, 2821–2823. doi:10.1021/ma00212a039

Return to citation in text: [1] -

Harada, A.; Kamachi, M. J. Chem. Soc., Chem. Commun. 1990, 1322–1323. doi:10.1039/C39900001322

Return to citation in text: [1] -

Li, J.; Harada, A.; Kamachi, M. Polym. J. 1994, 26, 1019–1026. doi:10.1295/polymj.26.1019

Return to citation in text: [1] -

Kawaguchi, Y.; Harada, A. J. Am. Chem. Soc. 2000, 122, 3797–3798. doi:10.1021/ja9943647

Return to citation in text: [1] -

Harada, A.; Adachi, H.; Kawaguchi, Y.; Okada, M.; Kamachi, M. Polym. J. 1996, 28, 159–163. doi:10.1295/polymj.28.159

Return to citation in text: [1] -

Meier, L. P.; Heule, M.; Caseri, W. R.; Shelden, R. A.; Suter, U. W.; Wenz, G.; Keller, B. Macromolecules 1996, 29, 718–723. doi:10.1021/ma946428y

Return to citation in text: [1] -

Wenz, G.; Gruber, C.; Keller, B.; Schilli, C.; Albuzat, T.; Müller, A. Macromolecules 2006, 39, 8021–8026. doi:10.1021/ma061033n

Return to citation in text: [1] -

Nelson, A.; Belitsky, J. M.; Vidal, S.; Joiner, C. S.; Baum, L. G.; Stoddart, J. F. J. Am. Chem. Soc. 2004, 126, 11914–11922. doi:10.1021/ja0491073

Return to citation in text: [1] -

Saito, H.; Yonemura, H.; Nakamura, H.; Matsuo, T. Chem. Lett. 1990, 19, 535–538. doi:10.1246/cl.1990.535

Return to citation in text: [1] -

Ohga, K.; Takashima, Y.; Takahashi, H.; Kawaguchi, Y.; Yamaguchi, H.; Harada, A. Macromolecules 2005, 38, 5897–5904. doi:10.1021/ma0508606

Return to citation in text: [1]

| 1. | Gandhi, M. V.; Thompson, B. S. Smart Materials and Structures; Chapman & Hall: London, 1992. |

| 2. | Urban, M. W., Ed. Handbook of Stimuli-Responsive Materials; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2011. |

| 3. | Minko, S., Ed. Responsive Polymer Materials: Design and Applications; Blackwell Pub.: Ames, IA, USA, 2006. |

| 12. | Liu, Y.; You, C.-C.; Zhang, H.-Y.; Kang, S.-Z.; Zhu, C.-F.; Wang, C. Nano Lett. 2001, 1, 613–616. doi:10.1021/nl015550p |

| 13. | Liu, Y.; Li; Fan, Z.; Zhang, H.-Y.; Wu, X.; Guan, X.-D.; Liu, S.-X. Nano Lett. 2002, 2, 257–261. doi:10.1021/nl015670x |

| 14. | Liu, Y.; Li; Zhang, H.-Y.; Zhao, Y.-L.; Wu, X. Macromolecules 2002, 35, 9934–9938. doi:10.1021/ma025541i |

| 15. | Liu, Y.; Song, Y.; Wang, H.; Zhang, H.-Y.; Li, X.-Q. Macromolecules 2004, 37, 6370–6375. doi:10.1021/ma049929k |

| 11. | Kretschmann, O.; Choi, S. W.; Miyauchi, M.; Tomatsu, I.; Harada, A.; Ritter, H. Angew. Chem., Int. Ed. 2006, 45, 4361–4365. doi:10.1002/anie.200504539 |

| 10. | Okumura, Y.; Ito, K. Adv. Mater. 2001, 13, 485–487. doi:10.1002/1521-4095(200104)13:7<485::AID-ADMA485>3.0.CO;2-T |

| 4. | Beaty, C. E.; Saltzman, W. M. J. Controlled Release 1993, 24, 15–23. doi:10.1016/0168-3659(93)90165-2 |

| 5. | Kim, S.; Healy, K. E. Biomacromolecules 2003, 4, 1214–1223. doi:10.1021/bm0340467 |

| 6. | Mahoney, M. J.; Anseth, K. S. Biomaterials 2006, 27, 2265–2274. doi:10.1016/j.biomaterials.2005.11.007 |

| 7. | Petka, W. A.; Harden, J. L.; McGrath, K. P.; Wirtz, D.; Tirrell, D. A. Science 1998, 281, 389–392. doi:10.1126/science.281.5375.389 |

| 8. | Shen, W.; Lammertink, R. G. H.; Sakata, J. K.; Kornfield, J. A.; Tirrell, D. A. Macromolecules 2005, 38, 3909–3916. doi:10.1021/ma048348s |

| 9. | Hennink, W. E.; van Nostrum, C. F. Adv. Drug Delivery Rev. 2002, 54, 13–36. doi:10.1016/S0169-409X(01)00240-X |

| 19. | Kawaguchi, Y.; Harada, A. J. Am. Chem. Soc. 2000, 122, 3797–3798. doi:10.1021/ja9943647 |

| 20. | Harada, A.; Adachi, H.; Kawaguchi, Y.; Okada, M.; Kamachi, M. Polym. J. 1996, 28, 159–163. doi:10.1295/polymj.28.159 |

| 24. | Saito, H.; Yonemura, H.; Nakamura, H.; Matsuo, T. Chem. Lett. 1990, 19, 535–538. doi:10.1246/cl.1990.535 |

| 18. | Li, J.; Harada, A.; Kamachi, M. Polym. J. 1994, 26, 1019–1026. doi:10.1295/polymj.26.1019 |

| 25. | Ohga, K.; Takashima, Y.; Takahashi, H.; Kawaguchi, Y.; Yamaguchi, H.; Harada, A. Macromolecules 2005, 38, 5897–5904. doi:10.1021/ma0508606 |

| 16. | Harada, A.; Kamachi, M. Macromolecules 1990, 23, 2821–2823. doi:10.1021/ma00212a039 |

| 17. | Harada, A.; Kamachi, M. J. Chem. Soc., Chem. Commun. 1990, 1322–1323. doi:10.1039/C39900001322 |

| 10. | Okumura, Y.; Ito, K. Adv. Mater. 2001, 13, 485–487. doi:10.1002/1521-4095(200104)13:7<485::AID-ADMA485>3.0.CO;2-T |

| 21. | Meier, L. P.; Heule, M.; Caseri, W. R.; Shelden, R. A.; Suter, U. W.; Wenz, G.; Keller, B. Macromolecules 1996, 29, 718–723. doi:10.1021/ma946428y |

| 22. | Wenz, G.; Gruber, C.; Keller, B.; Schilli, C.; Albuzat, T.; Müller, A. Macromolecules 2006, 39, 8021–8026. doi:10.1021/ma061033n |

| 23. | Nelson, A.; Belitsky, J. M.; Vidal, S.; Joiner, C. S.; Baum, L. G.; Stoddart, J. F. J. Am. Chem. Soc. 2004, 126, 11914–11922. doi:10.1021/ja0491073 |

© 2012 Takashima et al; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (http://www.beilstein-journals.org/bjoc)