Abstract

A novel compound based on a glutamic acid skeleton, containing azobenzene as a photoresponsive group and ureidopyrimidinone (UPy) as a connection site, was designed and synthesized. The monomer is capable of forming an organogel in nonpolar organic solvents and different types of nanostructures in other solvents. The state of the gel and the chirality of the nanostructures could both be adjusted by subsequent light irradiation at different wavelengths. The helical nanofiber-like morphology was verified in the internal structure of the gel. The performance of this gel was investigated by a series of methods, such as UV–vis absorption spectroscopy, circular dichroism, scanning electron microscopy and rheological techniques. This work provides a new method for facile synthesis of chiro-optical gels.

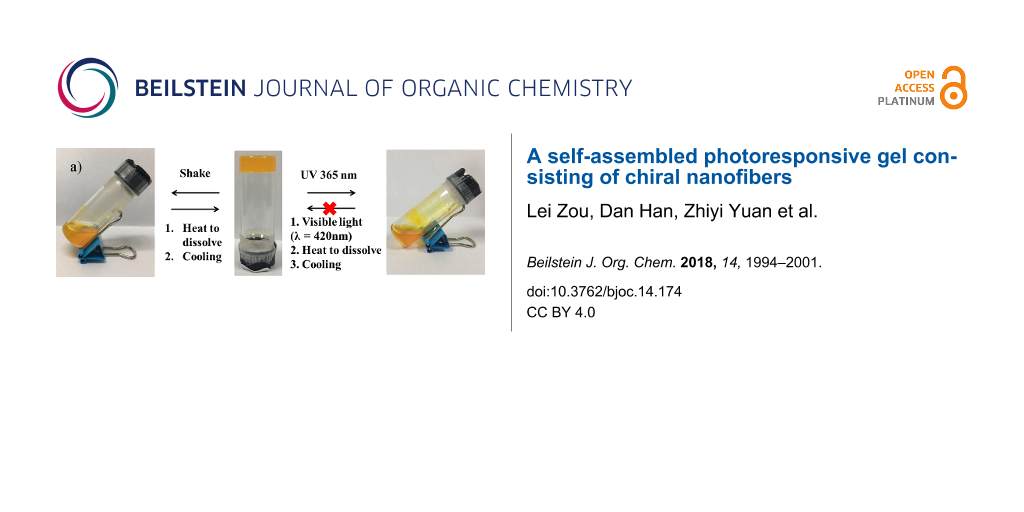

Graphical Abstract

Introduction

Supramolecular gels [1,2] immobilized by three-dimensional networks through self-assembly have drawn significant attention in the past decades. They are normally fabricated by means of noncovalent intermolecular interactions [3], such as π–π stacking, hydrogen bonding, van der Waals forces, hydrophobic, electrostatic, host–guest and other interactions. Interestingly, some of them can be assembled into distinctive nanostructures through gel formation [4-6].

Various functional nanostructures have shown great potential for applications in many important areas, for example, nanofabrication [5,7-10], drug delivery [11,12], and chemosensing [13,14]. Among the supramolecular gels, the low-molecular-weight gels (LMWGs) [15,16] are those that self-assemble into gels in organic solvents with molecular weights of <2000 Da. The weak noncovalent intermolecular interactions between LMWGs make them more sensitive to external conditions [6,17-19], such as solvent, light and temperature. These characteristics meet currents demands for conveniently controlling the assembly of materials according to their size, shape, and morphology.

Chiral functional materials have aroused much attention for their potential applications. Liu and co-workers [20-31] have built a multifunctional controllable gel system, which utilized L-glutamic lipid to construct nanofibers, nanotwists, and nanotubes with the property of chirality. Azobenzene, which is structurally photosensitive, is widely chosen to construct optically controlled systems [17,30,32-35]. This moiety is also frequently employed as a building block because of its strong π–π stacking in nonpolar solvents.

Herein, a novel compound 3 containing both chiral L-glutamic lipid and azobenzene was designed and synthesized (Scheme 1). It is used as a candidate to form a new chiro-optical system [30,36-41]. Ureidopyrimidinone (UPy), as a connection site, is also introduced to make quadruple hydrogen bonding [42-44]. The structure and schematic representation of 3 are shown in Figure 1. The possible assembly process of the nanostructure is proposed as well. It is found that compound 3 is able to form a gel in nonpolar solvents. The assembled structures of 3 in different solvents were also investigated. The photoresponsiveness of the formed nanostructure was investigated concomitantly as well.

Figure 1: The chemical structure and the schematic representation of compound 3 as well as the proposed assembly process of the nanostructure.

Figure 1: The chemical structure and the schematic representation of compound 3 as well as the proposed assem...

Results and Discussion

The monomolecular compound 3 can be easily synthesized in 3 steps. The compound has the necessary features for gel formation. The quadruple hydrogen bonding created by UPy moieties is quite stable in nonpolar solvents. Therefore, the molecule can easily assemble into dimers. Then, the trans-isomers of azobenzene can stack with each other via π–π interactions. Further, the acylamino group of the glutamic acid moiety at the center of the molecule also promotes this aggregation through hydrogen bonding interactions. Finally, the chirality of glutamic acid may be magnified along with the formation of supramolecular structure.

To investigate the potential photoresponsiveness of compound 3, the UV–vis absorption spectrum was measured to trace photochemical and photophysical properties of the solution of compound 3 (1.0 × 10−5 M in chloroform). As shown in Figure 2, the azobenzene trans-isomer displayed a strong absorbance peak at 352 nm. When exposed to ultraviolet light of 365 nm, the peak at 352 nm obviously decreased and reached a photostationary state within 5 minutes. The equilibrium could be reversed by subsequent exposure to visible light (420 nm) and UV light (365 nm) irradiation, whereby the equilibrium could be reached within 6 min and 4 min, respectively. However, the fatigue durability of this compound did not meet the expected requirement; after two cycles of light irradiation, the photoresponsiveness was clearly weakened. This defect may be ascribed to the rigid structure of compound 3. These two azobenzene moieties within the molecule are close and the dimerization of the UPy moiety results in a more crowded structure.

![[1860-5397-14-174-2]](/bjoc/content/figures/1860-5397-14-174-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: UV–vis absorbance spectra of a) compound 3 and b) irradiated by a light source of 365 nm and c) then treated by light of 420 nm. The concentration was 1.0 × 10−5 M in CHCl3.

Figure 2: UV–vis absorbance spectra of a) compound 3 and b) irradiated by a light source of 365 nm and c) the...

The circular dichroism (CD) spectrum was then measured to trace the different states of aggregation in solution of compound 3 in different solvents. Benzene, toluene, p-xylene, chloroform, tetrachloromethane and DMSO were chosen as solvents to prepare solutions with uniform concentration (3.0 × 10−5 M). As evidenced in the CD spectrum (Figure 3), the CD signal in a solution of DMSO and chloroform was very weak, and the CD signal in tetrachloromethane and p-xylene was not very strong but discernible. On the other hand, the CD signal in aromatic solvents, like benzene and toluene, was strong enough to confirm the formation of chiral structures. These results indicate that the chiral nanostructures can be only obtained in solvents with lower polarity, especially in aromatic solvents.

![[1860-5397-14-174-3]](/bjoc/content/figures/1860-5397-14-174-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: CD spectrum of compound 3 in solutions of a) benzene, toluene, p-xylene, chloroform, tetrachloromethane and DMSO with identical concentration (3.0 × 10−5 M), b) before and after being exposed to UV (λ = 365 nm) and visible (λ = 420 nm) light.

Figure 3: CD spectrum of compound 3 in solutions of a) benzene, toluene, p-xylene, chloroform, tetrachloromet...

To study the chirality of compound 3 and its reaction to light stimulation, 3 (in CCl4) was exposed to visible irradiation or UV light. The CD spectrum was then recorded. In Figure 3b, two obvious peaks at 300 nm and 375 nm evidence the existence of the chiral structure in the solution. This CD signal disappeared after irradiation with light at 365 nm, implying that the chiral structure in the solution had been destroyed. The obvious chiral signal reappeared when the same solution was exposed to visible light of 420 nm before reaching a stable state. However, this process was partially reversible. The compound 3 cycling test, with more than 8 cycles, caused the total disappearance of the CD signal and the process was then no longer reversible (Figure S8, Supporting Information File 1).

The morphology of compound 3 was further characterized by scanning electron microscopy (SEM, Figure 4). The samples were prepared by evaporating the solution of compound 3 on a surface of mica, and the differences in various solvents were also investigated. The sample in DMSO did not show a chiral self-assembled nanostructure owing to the destruction of quadruple hydrogen bonding and π–π stacking in DMSO. However, beautiful acicular fibers could be detected on the surface treated with a chloroform solution, and a dendritic network was observed on the sample made from benzene solution (Figure S9, Supporting Information File 1). The photoresponsiveness of compound 3 was also investigated by drying the chloroform solution of compound 3, which was exposed to sufficient UV light (365 nm) beforehand, on the surface of mica and detected by SEM, whereby only small discs were found as shown in Figure 4b. This implies that the UV light of 365 nm can efficiently destroy the self-assembled structure, and the nanostructures of the assembled compound 3 can be adjusted by both solvent and light.

![[1860-5397-14-174-4]](/bjoc/content/figures/1860-5397-14-174-4.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 4: SEM images of the microstructure a) obtained by the self-assembled compound 3 in CHCl3 on the surface of mica and then b) treated with UV light (365 nm).

Figure 4: SEM images of the microstructure a) obtained by the self-assembled compound 3 in CHCl3 on the surfa...

The formation of organogels in various solvents was conducted to test the gelation ability of compound 3. The gel was fabricated by melting compound 3 in solution by heating for about 20 min, followed by allowing the solution to rest at room temperature for 30 min. The gelation ability of compound 3 in various organic solvents was investigated by using the “stable to inversion of a test tube” method (Figure 5a). Here we arrive at the conclusion that compound 3 can only form an organogel in nonpolar aromatic solvents such as benzene and p-xylene. Table 1 lists the solvent parameters and the gel-forming ability of compound 3 in various organic solvents. The critical gelation concentration (CGC) is also noted. We took the gel formed in benzene as the example for the following investigations. The rheological technique (Figure 5b) was used to measure the rheological properties of this gel system first. The dynamic frequency spectra of the gel indicated that the elastic modulus G’ was higher than the viscous modulus G” when the frequency ω was between 0.1 and 100 Hz. This showed that the system conforms to the character of the gel. However, the gel is not stable under shaking, where it is broken into a mixture of solution and small pieces. After melting these particles again then natural cooling, the gel state was once again obtained.

Table 1: Gelation ability of compound 3 in various organic solvents.

| solvent | CGCa [mg mL−1] |

|---|---|

| hexane | P |

| cyclohexane | P |

| CCl4 | G (7.5) |

| benzene | G (6.5) |

| methylbenzene | HG |

| p-xylene | G (5.0) |

| CHCl3 | S |

| CH2Cl2 | S |

| THF | S |

| acetone | S |

| acetonitrile | S |

| DMF | S |

aG = gel; P = precipitation; S = solution; HG = half gel.

![[1860-5397-14-174-5]](/bjoc/content/figures/1860-5397-14-174-5.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 5: a) The gel-to-sol transformation of the samples via different routes. b) Dynamic frequency sweep of the gel fabricated in benzene. (c,d) FESEM images of compound 3 xerogels.

Figure 5: a) The gel-to-sol transformation of the samples via different routes. b) Dynamic frequency sweep of...

Field emission scanning electron microscopy (FESEM) was utilized to characterize the xerogels obtained by freeze drying. As shown in Figure 5c,d, plenty of helical nanotwists could be found in the xerogel. These fibers were intertwined together to form a 3D nanostructure. This result partially showed the gel formation pathway. Compound 3 may form dimers at the beginning, which can be detected by high-resolution mass spectrometry (Figure S7, Supporting Information File 1). Then, the dimers and single molecules 3 were able to assemble together through π–π stacking and hydrogen bonding to fabricate the nanofibers. Finally, those fibers twisted with each other to form nanotwists of wider diameter.

Finally, the gel system was irradiated with ultraviolet light or visible light to test its stimuli response. Under 365 nm light exposure, the gel melted into a turbid liquid within 20 min. However, the system could not easily be reversed due to the poor reversibility of compound 3 in benzene that was investigated previously.

Conclusion

We have synthesized a novel chiral compound containing azobenzene as the photoresponsive group and UPy as the connection site. The monomer was capable of forming chiral nanostructures and a low-molecular-weight organogel in nonpolar organic solvents. The monomer also can form different types of nanostructures in different solvents, and the kind of solvent was found to be crucial for the chirality of the assembled structure. The gel-to-sol process could also be modified by shaking and UV light. The rheological behavior of the gel was investigated and found to meet the basic requirement of a gel. The inner structure of the gel was determined to be a cross-linked network made of chiral nanotwists. This work provides a novel method to build chiro-optical soft material systems.

Experimental

Synthesis of compound 1

1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC·HCl, 8.04 g, 0.044 mol) and 1-hydroxybenzotriazole (HOBt, 5.94 g,0.044 mol) were added to a 200 mL CH2Cl2 solution of Boc-L-glutamic acid (5 g, 0.02 mol) and 4-aminoazobenzene (7.8838 g, 0.04 mol), then the obtained mixture was stirred at room temperature for 72 h under an Ar atmosphere. The obtained yellow solid was isolated by filtration and washed three times with CH2Cl2. The crude product was recrystallized from THF/H2O to yield compound 1 as a yellow solid (10.53 g, 87% yield). 1H NMR (400 MHz, DMSO-d6) δ 10.43 (s, 1H), 10.33 (s, 1H), 8.02–7.71 (m, 12H), 7.68–7.43 (m, 6H), 7.22 (d, J = 7.6 Hz, 1H), 4.18 (dd, J = 13.5, 7.9 Hz, 1H), 2.17–1.90 (m, 2H), 1.36 (d, J = 34.1 Hz, 9H); 13C NMR (100 MHz, DMSO-d6) δ 171.44, 170.83, 155.43, 151.99, 147.58, 147.35, 142.35, 142.05, 131.04, 130.97, 129.38, 123.64, 122.32, 122.28, 119.50, 119.17, 78.23, 54.78, 32.92, 28.17, 27.07, 25.09; HRMS m/z: [M + H]+ calcd for C34H36N7O4+, 606.2829; found, 606.2830.

Synthesis of compound 3

Compound 2 was easily prepared according to a literature method [45]. Five mL of trifluoroacetic acid was dropped into a 25 mL CH2Cl2 solution of compound 1 (1.0 g, 1.65 mmol), then the mixture was stirred at room temperature for 2 h under an Ar atmosphere. Evaporation of the resulting red solution was performed under reduced pressure, and small amounts of CH2Cl2 was frequently added to the bottle until the trifluoroacetic acid was removed entirely. The resulting yellow solid was added to an acetone solution of compound 2 (1.22 g, 4.03 mmol) under an Ar atmosphere, then the mixture was heated at reflux for 24 h. The evaporation (under reduced pressure) and further purification of the resulting solution was carried out by column chromatography using CH2Cl2/CH3OH (50:1, v/v) and CH2Cl2/CH3OH (10:1, v/v) to afford 3 as a yellow solid (620 mg, 62.5% yield). 1H NMR (400 MHz, DMSO) δ 11.29 (s, 1H), 10.67 (s, 1H), 10.34 (s, 1H), 9.68 (s, 1H), 8.30 (s, 1H), 8.01–7.68 (m, 12H), 7.68–7.43 (m, 6H), 5.77 (s, 1H), 4.64 (s, 1H), 2.22 (dd, J = 13.5, 6.0 Hz, 2H), 2.05 (dd, J = 13.6, 6.7 Hz, 1H), 1.55 (dd, J = 15.8, 10.0 Hz, 4H), 1.29–1.04 (m, 6H), 0.85–0.71 (m, 6H); 13C NMR (100 MHz, DMSO) δ 170.51, 151.99, 147.79, 147.34, 142.30, 141.65, 131.11, 130.96, 129.41, 129.37, 123.57, 122.34, 122.26, 119.70, 119.17, 53.14, 29.13, 22.15, 13.86, 11.84; HRMS m/z: [M + Na]+ calcd for C41H44N10O4Na+, 763.3445; found, 763.3443.

Supporting Information

| Supporting Information File 1: Additional schemes and figures, general remarks, synthesis and characterization data, including copies of 1H and 13C NMR spectra. | ||

| Format: PDF | Size: 1.0 MB | Download |

References

-

Babu, S. S.; Praveen, V. K.; Ajayaghosh, A. Chem. Rev. 2014, 114, 1973–2129. doi:10.1021/cr400195e

Return to citation in text: [1] -

Ma, X.; Tian, H. Acc. Chem. Res. 2014, 47, 1971–1981. doi:10.1021/ar500033n

Return to citation in text: [1] -

Zhou, Z.; Yan, X.; Cook, T. R.; Saha, M. L.; Stang, P. J. J. Am. Chem. Soc. 2016, 138, 806–809. doi:10.1021/jacs.5b12986

Return to citation in text: [1] -

Zhang, L.; Qin, L.; Wang, X.; Cao, H.; Liu, M. Adv. Mater. 2014, 26, 6959–6964. doi:10.1002/adma.201305422

Return to citation in text: [1] -

Xu, C.; Xu, L.; Ma, X. Chin. Chem. Lett. 2018, 29, 970–972. doi:10.1016/j.cclet.2017.11.045

Return to citation in text: [1] [2] -

Ma, X.; Tian, H. Acta Polym. Sin. 2017, 1, 27–36.

Return to citation in text: [1] [2] -

Zhang, Q.; Qu, D.-H.; Ma, X.; Tian, H. Chem. Commun. 2013, 49, 9800–9802. doi:10.1039/c3cc46297h

Return to citation in text: [1] -

Li, T.; Li, X.; Wang, J.; Ågren, H.; Ma, X.; Tian, H. Adv. Opt. Mater. 2016, 4, 840–847. doi:10.1002/adom.201500694

Return to citation in text: [1] -

Wang, S.; Wang, F.; Li, C.; Li, T.; Cao, D.; Ma, X. Sci. China: Chem. 2018, 61, in press.

Return to citation in text: [1] -

Zhang, Q.; Yao, X.; Qu, D.-H.; Ma, X. Chem. Commun. 2014, 50, 1567–1569. doi:10.1039/c3cc48491b

Return to citation in text: [1] -

Fong, W.-K.; Hanley, T. L.; Thierry, B.; Kirby, N.; Boyd, B. J. Langmuir 2010, 26, 6136–6139. doi:10.1021/la100644s

Return to citation in text: [1] -

Du, J. D.; Hong, L.; Tan, A.; Boyd, B. J. J. Phys. Chem. B 2018, 122, 1766–1770. doi:10.1021/acs.jpcb.7b12234

Return to citation in text: [1] -

Salvia, M.-V.; Salassa, G.; Rastrelli, F.; Mancin, F. J. Am. Chem. Soc. 2015, 137, 11399–11406. doi:10.1021/jacs.5b06300

Return to citation in text: [1] -

Hortalá, M. A.; Fabbrizzi, L.; Marcotte, N.; Stomeo, F.; Taglietti, A. J. Am. Chem. Soc. 2003, 125, 20–21. doi:10.1021/ja027110l

Return to citation in text: [1] -

Wang, X.; Duan, P.; Liu, M. Chem. – Asian J. 2014, 9, 770–778. doi:10.1002/asia.201301518

Return to citation in text: [1] -

Geng, H.; Ye, L.; Zhang, A.-y.; Li, J.; Feng, Z.-g. Langmuir 2016, 32, 4586–4594. doi:10.1021/acs.langmuir.6b01059

Return to citation in text: [1] -

Koumura, N.; Kudo, M.; Tamaoki, N. Langmuir 2004, 20, 9897–9900. doi:10.1021/la048334f

Return to citation in text: [1] [2] -

Duan, P.; Li, Y.; Li, L.; Deng, J.; Liu, M. J. Phys. Chem. B 2011, 115, 3322–3329. doi:10.1021/jp110636b

Return to citation in text: [1] -

Cai, Y.; Guo, Z.; Chen, J.; Li, W.; Zhong, L.; Gao, Y.; Jiang, L.; Chi, L.; Tian, H.; Zhu, W.-H. J. Am. Chem. Soc. 2016, 138, 2219–2224. doi:10.1021/jacs.5b11580

Return to citation in text: [1] -

Jiang, H.; Zhang, L.; Chen, J.; Liu, M. ACS Nano 2017, 11, 12453–12460. doi:10.1021/acsnano.7b06484

Return to citation in text: [1] -

Liu, C.; Yang, D.; Jin, Q.; Zhang, L.; Liu, M. Adv. Mater. 2016, 28, 1644–1649. doi:10.1002/adma.201504883

Return to citation in text: [1] -

Qin, L.; Duan, P.; Xie, F.; Zhang, L.; Liu, M. Chem. Commun. 2013, 49, 10823–10825. doi:10.1039/c3cc47004k

Return to citation in text: [1] -

Shen, Z.; Wang, T.; Liu, M. Chem. Commun. 2014, 50, 2096–2099. doi:10.1039/c3cc48350a

Return to citation in text: [1] -

Wang, X.; Duan, P.; Liu, M. Chem. Commun. 2012, 48, 7501–7503. doi:10.1039/c2cc33246a

Return to citation in text: [1] -

Li, Y.; Wang, T.; Liu, M. Soft Matter 2007, 3, 1312–1317. doi:10.1039/b710165a

Return to citation in text: [1] -

Xie, F.; Qin, L.; Liu, M. Chem. Commun. 2016, 52, 930–933. doi:10.1039/c5cc08076b

Return to citation in text: [1] -

Duan, P.; Qin, L.; Zhu, X.; Liu, M. Chem. – Eur. J. 2011, 17, 6389–6395. doi:10.1002/chem.201003049

Return to citation in text: [1] -

Duan, P.; Liu, M. Phys. Chem. Chem. Phys. 2010, 12, 4383–4389. doi:10.1039/b923595g

Return to citation in text: [1] -

Zhang, L.; Wang, X.; Wang, T.; Liu, M. Small 2015, 11, 1025–1038. doi:10.1002/smll.201402075

Return to citation in text: [1] -

Cao, H.; Jiang, J.; Zhu, X.; Duan, P.; Liu, M. Soft Matter 2011, 7, 4654–4660. doi:10.1039/c1sm05219e

Return to citation in text: [1] [2] [3] -

Jin, X.; Jiang, J.; Liu, M. ACS Nano 2016, 10, 11179–11186. doi:10.1021/acsnano.6b06233

Return to citation in text: [1] -

Yang, D.; Zhang, L.; Yin, L.; Zhao, Y.; Zhang, W.; Liu, M. Soft Matter 2017, 13, 6129–6136. doi:10.1039/c7sm00935f

Return to citation in text: [1] -

Ji, L.; Ouyang, G.; Liu, M. Langmuir 2017, 33, 12419–12426. doi:10.1021/acs.langmuir.7b02285

Return to citation in text: [1] -

Xie, F.; Ouyang, G.; Qin, L.; Liu, M. Chem. – Eur. J. 2016, 22, 18208–18214. doi:10.1002/chem.201603998

Return to citation in text: [1] -

Liu, Z.-X.; Feng, Y.; Yan, Z.-C.; He, Y.-M.; Liu, C.-Y.; Fan, Q.-H. Chem. Mater. 2012, 24, 3751–3757. doi:10.1021/cm302318b

Return to citation in text: [1] -

Zhu, X.; Li, Y.; Duan, P.; Liu, M. Chem. – Eur. J. 2010, 16, 8034–8040. doi:10.1002/chem.201000595

Return to citation in text: [1] -

Jung, S. H.; Jeon, J.; Kim, H.; Jaworski, J.; Jung, J. H. J. Am. Chem. Soc. 2014, 136, 6446–6452. doi:10.1021/ja5018199

Return to citation in text: [1] -

Cao, H.; Yuan, Q.; Zhu, X.; Zhao, Y.-P.; Liu, M. Langmuir 2012, 28, 15410–15417. doi:10.1021/la303263g

Return to citation in text: [1] -

Wang, Y.; Xu, J.; Wang, Y.; Chen, H. Chem. Soc. Rev. 2013, 42, 2930–2962. doi:10.1039/c2cs35332f

Return to citation in text: [1] -

Niu, D.; Ji, L.; Ouyang, G.; Liu, M. Chem. Commun. 2018, 54, 1137–1140. doi:10.1039/c7cc09049h

Return to citation in text: [1] -

Cao, H.; Zhu, X.; Liu, M. Angew. Chem., Int. Ed. 2013, 52, 4122–4126. doi:10.1002/anie.201300444

Return to citation in text: [1] -

Miao, W.; Wang, S.; Liu, M. Adv. Funct. Mater. 2017, 27, 1701368. doi:10.1002/adfm.201701368

Return to citation in text: [1] -

Wang, Q.; Cheng, M.; Jiang, J.-L.; Wang, L.-Y. Chin. Chem. Lett. 2017, 28, 793–797. doi:10.1016/j.cclet.2017.02.008

Return to citation in text: [1] -

Li, Q.; Liu, C.; Wen, J.; Wu, Y.; Shan, Y.; Liao, J. Chin. Chem. Lett. 2017, 28, 1857–1874. doi:10.1016/j.cclet.2017.05.007

Return to citation in text: [1] -

Keizer, H. M.; Sijbesma, R. P.; Meijer, E. W. Eur. J. Org. Chem. 2004, 2553–2555. doi:10.1002/ejoc.200300752

Return to citation in text: [1]

| 1. | Babu, S. S.; Praveen, V. K.; Ajayaghosh, A. Chem. Rev. 2014, 114, 1973–2129. doi:10.1021/cr400195e |

| 2. | Ma, X.; Tian, H. Acc. Chem. Res. 2014, 47, 1971–1981. doi:10.1021/ar500033n |

| 11. | Fong, W.-K.; Hanley, T. L.; Thierry, B.; Kirby, N.; Boyd, B. J. Langmuir 2010, 26, 6136–6139. doi:10.1021/la100644s |

| 12. | Du, J. D.; Hong, L.; Tan, A.; Boyd, B. J. J. Phys. Chem. B 2018, 122, 1766–1770. doi:10.1021/acs.jpcb.7b12234 |

| 5. | Xu, C.; Xu, L.; Ma, X. Chin. Chem. Lett. 2018, 29, 970–972. doi:10.1016/j.cclet.2017.11.045 |

| 7. | Zhang, Q.; Qu, D.-H.; Ma, X.; Tian, H. Chem. Commun. 2013, 49, 9800–9802. doi:10.1039/c3cc46297h |

| 8. | Li, T.; Li, X.; Wang, J.; Ågren, H.; Ma, X.; Tian, H. Adv. Opt. Mater. 2016, 4, 840–847. doi:10.1002/adom.201500694 |

| 9. | Wang, S.; Wang, F.; Li, C.; Li, T.; Cao, D.; Ma, X. Sci. China: Chem. 2018, 61, in press. |

| 10. | Zhang, Q.; Yao, X.; Qu, D.-H.; Ma, X. Chem. Commun. 2014, 50, 1567–1569. doi:10.1039/c3cc48491b |

| 4. | Zhang, L.; Qin, L.; Wang, X.; Cao, H.; Liu, M. Adv. Mater. 2014, 26, 6959–6964. doi:10.1002/adma.201305422 |

| 5. | Xu, C.; Xu, L.; Ma, X. Chin. Chem. Lett. 2018, 29, 970–972. doi:10.1016/j.cclet.2017.11.045 |

| 6. | Ma, X.; Tian, H. Acta Polym. Sin. 2017, 1, 27–36. |

| 45. | Keizer, H. M.; Sijbesma, R. P.; Meijer, E. W. Eur. J. Org. Chem. 2004, 2553–2555. doi:10.1002/ejoc.200300752 |

| 3. | Zhou, Z.; Yan, X.; Cook, T. R.; Saha, M. L.; Stang, P. J. J. Am. Chem. Soc. 2016, 138, 806–809. doi:10.1021/jacs.5b12986 |

| 20. | Jiang, H.; Zhang, L.; Chen, J.; Liu, M. ACS Nano 2017, 11, 12453–12460. doi:10.1021/acsnano.7b06484 |

| 21. | Liu, C.; Yang, D.; Jin, Q.; Zhang, L.; Liu, M. Adv. Mater. 2016, 28, 1644–1649. doi:10.1002/adma.201504883 |

| 22. | Qin, L.; Duan, P.; Xie, F.; Zhang, L.; Liu, M. Chem. Commun. 2013, 49, 10823–10825. doi:10.1039/c3cc47004k |

| 23. | Shen, Z.; Wang, T.; Liu, M. Chem. Commun. 2014, 50, 2096–2099. doi:10.1039/c3cc48350a |

| 24. | Wang, X.; Duan, P.; Liu, M. Chem. Commun. 2012, 48, 7501–7503. doi:10.1039/c2cc33246a |

| 25. | Li, Y.; Wang, T.; Liu, M. Soft Matter 2007, 3, 1312–1317. doi:10.1039/b710165a |

| 26. | Xie, F.; Qin, L.; Liu, M. Chem. Commun. 2016, 52, 930–933. doi:10.1039/c5cc08076b |

| 27. | Duan, P.; Qin, L.; Zhu, X.; Liu, M. Chem. – Eur. J. 2011, 17, 6389–6395. doi:10.1002/chem.201003049 |

| 28. | Duan, P.; Liu, M. Phys. Chem. Chem. Phys. 2010, 12, 4383–4389. doi:10.1039/b923595g |

| 29. | Zhang, L.; Wang, X.; Wang, T.; Liu, M. Small 2015, 11, 1025–1038. doi:10.1002/smll.201402075 |

| 30. | Cao, H.; Jiang, J.; Zhu, X.; Duan, P.; Liu, M. Soft Matter 2011, 7, 4654–4660. doi:10.1039/c1sm05219e |

| 31. | Jin, X.; Jiang, J.; Liu, M. ACS Nano 2016, 10, 11179–11186. doi:10.1021/acsnano.6b06233 |

| 30. | Cao, H.; Jiang, J.; Zhu, X.; Duan, P.; Liu, M. Soft Matter 2011, 7, 4654–4660. doi:10.1039/c1sm05219e |

| 36. | Zhu, X.; Li, Y.; Duan, P.; Liu, M. Chem. – Eur. J. 2010, 16, 8034–8040. doi:10.1002/chem.201000595 |

| 37. | Jung, S. H.; Jeon, J.; Kim, H.; Jaworski, J.; Jung, J. H. J. Am. Chem. Soc. 2014, 136, 6446–6452. doi:10.1021/ja5018199 |

| 38. | Cao, H.; Yuan, Q.; Zhu, X.; Zhao, Y.-P.; Liu, M. Langmuir 2012, 28, 15410–15417. doi:10.1021/la303263g |

| 39. | Wang, Y.; Xu, J.; Wang, Y.; Chen, H. Chem. Soc. Rev. 2013, 42, 2930–2962. doi:10.1039/c2cs35332f |

| 40. | Niu, D.; Ji, L.; Ouyang, G.; Liu, M. Chem. Commun. 2018, 54, 1137–1140. doi:10.1039/c7cc09049h |

| 41. | Cao, H.; Zhu, X.; Liu, M. Angew. Chem., Int. Ed. 2013, 52, 4122–4126. doi:10.1002/anie.201300444 |

| 6. | Ma, X.; Tian, H. Acta Polym. Sin. 2017, 1, 27–36. |

| 17. | Koumura, N.; Kudo, M.; Tamaoki, N. Langmuir 2004, 20, 9897–9900. doi:10.1021/la048334f |

| 18. | Duan, P.; Li, Y.; Li, L.; Deng, J.; Liu, M. J. Phys. Chem. B 2011, 115, 3322–3329. doi:10.1021/jp110636b |

| 19. | Cai, Y.; Guo, Z.; Chen, J.; Li, W.; Zhong, L.; Gao, Y.; Jiang, L.; Chi, L.; Tian, H.; Zhu, W.-H. J. Am. Chem. Soc. 2016, 138, 2219–2224. doi:10.1021/jacs.5b11580 |

| 42. | Miao, W.; Wang, S.; Liu, M. Adv. Funct. Mater. 2017, 27, 1701368. doi:10.1002/adfm.201701368 |

| 43. | Wang, Q.; Cheng, M.; Jiang, J.-L.; Wang, L.-Y. Chin. Chem. Lett. 2017, 28, 793–797. doi:10.1016/j.cclet.2017.02.008 |

| 44. | Li, Q.; Liu, C.; Wen, J.; Wu, Y.; Shan, Y.; Liao, J. Chin. Chem. Lett. 2017, 28, 1857–1874. doi:10.1016/j.cclet.2017.05.007 |

| 15. | Wang, X.; Duan, P.; Liu, M. Chem. – Asian J. 2014, 9, 770–778. doi:10.1002/asia.201301518 |

| 16. | Geng, H.; Ye, L.; Zhang, A.-y.; Li, J.; Feng, Z.-g. Langmuir 2016, 32, 4586–4594. doi:10.1021/acs.langmuir.6b01059 |

| 13. | Salvia, M.-V.; Salassa, G.; Rastrelli, F.; Mancin, F. J. Am. Chem. Soc. 2015, 137, 11399–11406. doi:10.1021/jacs.5b06300 |

| 14. | Hortalá, M. A.; Fabbrizzi, L.; Marcotte, N.; Stomeo, F.; Taglietti, A. J. Am. Chem. Soc. 2003, 125, 20–21. doi:10.1021/ja027110l |

| 17. | Koumura, N.; Kudo, M.; Tamaoki, N. Langmuir 2004, 20, 9897–9900. doi:10.1021/la048334f |

| 30. | Cao, H.; Jiang, J.; Zhu, X.; Duan, P.; Liu, M. Soft Matter 2011, 7, 4654–4660. doi:10.1039/c1sm05219e |

| 32. | Yang, D.; Zhang, L.; Yin, L.; Zhao, Y.; Zhang, W.; Liu, M. Soft Matter 2017, 13, 6129–6136. doi:10.1039/c7sm00935f |

| 33. | Ji, L.; Ouyang, G.; Liu, M. Langmuir 2017, 33, 12419–12426. doi:10.1021/acs.langmuir.7b02285 |

| 34. | Xie, F.; Ouyang, G.; Qin, L.; Liu, M. Chem. – Eur. J. 2016, 22, 18208–18214. doi:10.1002/chem.201603998 |

| 35. | Liu, Z.-X.; Feng, Y.; Yan, Z.-C.; He, Y.-M.; Liu, C.-Y.; Fan, Q.-H. Chem. Mater. 2012, 24, 3751–3757. doi:10.1021/cm302318b |

© 2018 Zou et al.; licensee Beilstein-Institut.

This is an Open Access article under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0). Please note that the reuse, redistribution and reproduction in particular requires that the authors and source are credited.

The license is subject to the Beilstein Journal of Organic Chemistry terms and conditions: (https://www.beilstein-journals.org/bjoc)