Abstract

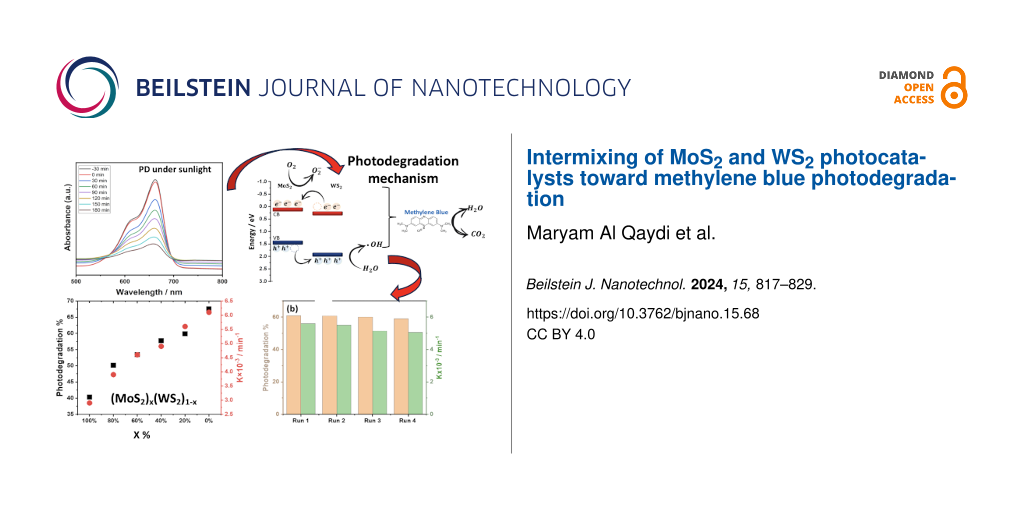

Visible-light-driven photocatalysis using layered materials has garnered increasing attention regarding the degradation of organic dyes. Herein, transition-metal dichalcogenides MoS2 and WS2 prepared by chemical vapor deposition as well as their intermixing are evaluated for photodegradation (PD) of methylene blue under solar simulator irradiation. Our findings revealed that WS2 exhibited the highest PD efficiency of 67.6% and achieved an impressive PD rate constant of 6.1 × 10−3 min−1. Conversely, MoS2 displayed a somewhat lower PD performance of 43.5% but demonstrated remarkable stability. The intriguing result of this study relies on the synergetic effect observed when both MoS2 and WS2 are combined in a ratio of 20% of MoS2 and 80% of WS2. This precise blend resulted in an optimized PD efficiency and exceptional stability reaching 97% upon several cycles. This finding underscores the advantageous outcomes of intermixing WS2 and MoS2, shedding light on the development of an efficient and enduring photocatalyst for visible-light-driven photodegradation of methylene blue.

Introduction

Water contamination has become a pressing global concern, threatening ecosystems, agriculture, and human well-being [1,2]. The massive industrialization has dramatically contributed to water pollution, which has prompted policymakers to put in place corrective actions for the development of efficient strategies for water treatment [3]. Following these measures, various technologies have proven their efficacy for water depollution, including adsorption and photocatalysis, and are often utilized for heavy metals, pharmaceuticals, pesticide removal, or synthetic dye degradation [4-6]. For instance, methylene blue (MB), which is considered one of the most used synthetic organic dyes in various industrial and medical applications, poses serious risks as a pollutant to water resources [7]. Indeed, MB is a potential carcinogen and mutagen, directly threatening human health if present in drinking water or in aquatic organisms [8]. In this context, photocatalysis has emerged as a reliable and environmentally friendly solution for MB photodegradation (PD) as it only consumes renewable energy, prevents the formation of secondary waste, and is a cost-effective technology. By harnessing impinging photons, the photocatalytic degradation of pollutants takes place at the interface between the photocatalyst surface and the MB-contaminated electrolyte. The photon energy is the driving force for breaking down the MB compound leading to its removal [9]. Typically, semiconductor-based photocatalysts, such as TiO2, ZnO2, and some other high-bandgap transition-metal dichalcogenides (TMD) have shown their ability to efficiently degrade the activated MB by irradiation [10,11].

Recently, TMD such as MoS2 and WS2, have displayed remarkable potential as cocatalysts. Their catalytic properties can be tailored based on their crystal structure, their surface area, and their morphology [12,13]. When TMD catalysts are intermixed, they form semiconductor–semiconductor junctions, enhancing their photocatalytic properties by promoting charge separation and electron transport [14,15]. At each stage of the photocatalytic process sequence, the intermixing of TMD materials is intended to efficiently enhance light absorption, photogeneration of charge carriers, and activation of the surface redox reaction [16,17]. Furthermore, TMD materials are known to possess favorable electrical conductivity, which allows them to serve as sites for trapping photogenerated charges. This, in turn, facilitates the collection of charge carriers [18] leading to interesting photodegradation properties [19,20]. During the photochemical reaction process, the light excitation induces the generation of electron–hole pairs (EHPs) [21]. The generated EHPs react with oxygen and water molecules to produce highly reactive species, such as hydroxyl radicals, which oxidize and degrade MB contaminants. Hence, evaluating the PD processes in the case of MoS2 and WS2 as TMD materials is crucial for optimizing their functionalities to design novel materials and devices with improved PD stability and durability [8-10].

Recently, researchers have investigated the use of MoS2 as a photocatalyst for the degradation of MB. They demonstrated that the MoS2–GO compound exhibited interesting PD performances, with over 99% degradation of MB achieved within 60 min under visible light exposure by using 10 mg of the catalyst to degrade 10 mg/L of MB [22]. Other works have shown that the MoS2–ZnO composite achieved 97% of MB photodegradation in ≈30 min under visible irradiation by using 250 mg/L of the catalyst to degrade 10 mg/L of MB [23]. Moreover, when MoS2 is mixed with SnO2, the MB photodegradation reaches up to ≈99.5% within 5 min. This rapid degradation occurred when 400 mg/L of the catalyst was used to degrade 3.2 mg/L of MB [24]. These results concerned materials fabricated using the hydrothermal technique, involving multiple processing stages. This ends up increasing the overall costs of production and creates a real challenge [25]. One can note the very high amount of catalyst used to degrade a small MB concentration. Besides, other studies have shown that WS2/polypyrrole composites synthesized by oxidative polymerization achieved a photodegradation efficiency of 96.15% in 180 min by using 100 mg of the catalyst to degrade 5 mg/L of MB [25]. Nevertheless, most of the reported studies concerned the use of complex heterostructure-based devices and a very high quantity of catalysts, which is not convenient for potential commercial upscaling.

In the present work, we report on a systematic study carried out to assess MB photodegradation using chemically vapor-deposited intermixed MoS2/WS2 at different ratios. The obtained results are compared and discussed based on their respective photodegradation yield, their physical properties, and their evolving microstructures.

Results and Discussion

Structural analysis

Raman spectroscopy analysis of the exfoliated samples revealed prominent vibrational modes of hexagonal 2H-MoS2, 2H-WS2, and mixture of both phases, represented by E12g at 382 cm−1 and A1g at 410 cm−1, respectively, for MoS2, 350 cm−1. It can be further resolved into two sub-peaks at 324 cm−1 and 351 cm−1, corresponding to the 2LA(M) and E12g modes, the A1g mode at 420 cm−1 for WS2, and the presence of combined vibration modes for the composite MoS2/WS2 as shown in Figure 1.

![[2190-4286-15-68-1]](/bjnano/content/figures/2190-4286-15-68-1.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 1: Raman spectroscopy for a) MoS2, b) WS2, and c) MoS2/WS2 composite.

Figure 1: Raman spectroscopy for a) MoS2, b) WS2, and c) MoS2/WS2 composite.

Interestingly, the positions of the E12g and A1g vibrational modes in the composite sample did not exhibit any noticeable shifts compared to the observed peaks in individual samples as reported in previous studies [26].

The X-ray diffraction (XRD) diagram shown in Figure 2a exhibits the diffraction peaks at 14.25°, 25.81°, 32.15°, 44.13°, and 60.21° positions, corresponding to (002), (004), (103), (006), and (008) planes of hexagonal 2H-MoS2. Likewise, Figure 2b displays the diffraction peaks at 14.3°, 28.8°, 43.9°, 59.8°, and 77.13° positions, attributed to (002), (004), (006), (008), and (0010) planes of 2H-WS2, respectively.

![[2190-4286-15-68-2]](/bjnano/content/figures/2190-4286-15-68-2.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 2: XRD diagrams for a) MoS2, b) WS2, and c) MoS2/WS2 composite.

Figure 2: XRD diagrams for a) MoS2, b) WS2, and c) MoS2/WS2 composite.

The XRD diagram depicted in Figure 2c reveals the combination of peaks arising from both 2H-MoS2 and 2H-WS2, confirming the successful intermixing of the MoS2/WS2 composite. The sharp shape of the diffraction peaks suggests a very good crystallinity of the fabricated materials. The recurring additional peaks observed in all XRD diagrams at ≈37° and ≈69° positions are due to the silicon substrate.

The X-ray photoelectron spectroscopy (XPS) survey scans and high-resolution scans for all samples are presented in Figure 3a–j. All XPS analyses were first calibrated using the C 1s peak of carbon at 284.6 eV (Supporting Information File 1, Figure S1). For the MoS2 scan, the deconvoluted peaks for Mo 3d show peaks centered around ≈230 eV and ≈233.1 eV corresponding to 3d5/2 and 3d3/2 peaks of Mo 3d [27-29]. A small peak appearing at around ≈227.2 eV is ascribed to S 2s (Figure 2b) [28]. In addition, the deconvoluted peaks of S 2p appear at ≈162.9 eV and ≈164.1 eV attributed to the S 2p doublet (2p3/2 and 2p1/2) as shown in Figure 3c [30].

![[2190-4286-15-68-3]](/bjnano/content/figures/2190-4286-15-68-3.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 3: XPS surveys and element edges a–c) MoS2, d–f) WS2, and g–j) MoS2/WS2 composite.

Figure 3: XPS surveys and element edges a–c) MoS2, d–f) WS2, and g–j) MoS2/WS2 composite.

High-resolution scans of W 4f and S 2p are shown in Figure 2e and Figure 2f, W 4f shows deconvoluted peaks at around ≈33.3 eV and ≈35.4 eV corresponding to the W 4f doublet (W 4f7/2 and W 4f5/2) [31]. An additional minor peak appearing at ≈38.7 eV is identified as W 5p3/2 [31]. The XPS analysis of the composite sample indicates the presence of the Mo 3d doublet peaks and S 2s peaks as well as the W 4f doublets, in addition to a peak appearing at ≈36.2 eV ascribed to W–O bonding [31]. This suggests the presence of minor oxidation of the flakes. Further quantitative analysis of XPS data indicates the following atomic compositions: Mo: 34.68%, S: 65.32%, W: 33.98%, S: 66.02%, and Mo: 14.06%, W: 23.70, S: 62.24%, respectively for MoS2, WS2, and MoS2/WS2 composite samples (e.g., Supporting Information File 1, Figure S2). The composition might vary from sample to sample to some extent depending on the efficiency of the sulfurization process. The XPS clubbed spectra for Mo 3d, S 2p, and W 4f indicate that there is no noticeable shifting in the peaks (the binding energies). This means there is no chemical shift in the compounds, implying that the intermixing of Mo and W did not disturb the chemical environment, and the elements retained a stable chemical bond.

Microstructure analysis

Figure 4 shows scanning electron microscopy (SEM) images of all considered samples. The specimens were prepared by drop casting a solution of the exfoliated samples on lacey carbon transmission electron microscopy (TEM) grids. Additionally, agglomeration of the flakes can be usually observed as well, which could be due to the effect of the solvent used for drop casting. The observed flakes have typical shapes such as triangular, hexagonal, pentagonal, and other irregular polygonal shapes. The size of the flakes is within the range of 1 µm. The morphology and the shape of the flakes have common microstructures of MoS2/WS2 materials grown using chemical vapor deposition (CVD) as previously reported [32]. This means that the samples are well preserved after exfoliation through the intense sonication process. Certain flakes can be observed to have bent. The edges in some flakes can be seen to lose the smoothness, which could be a result of the harsh sonication process. However, the distinct features of the flakes were overall conserved.

![[2190-4286-15-68-4]](/bjnano/content/figures/2190-4286-15-68-4.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 4: SEM images of exfoliated samples of a) MoS2, b) WS2, and c) MoS2/WS2 composite.

Figure 4: SEM images of exfoliated samples of a) MoS2, b) WS2, and c) MoS2/WS2 composite.

Figure 5 depicts TEM images carried out on the samples. Low- and high-resolution images captured from MoS2, WS2, and MoS2/WS2 composite samples are shown in Figure 5a–f. The low-magnification TEM image indicates that the size of the flakes is in a range of a few hundred nanometers to a few microns, as observed in the SEM images. Figure 5a and Figure 5b show that the MoS2 flake has a hexagonal crystal structure with an interplanar distance of 0.61 nm, corresponding to the (002) plane of 2H-MoS2 [33]. Other MoS2 crystal orientation is indicated by the (103) direction. In the high-resolution image, some edge-related defects can also be seen which is common in CVD-grown MoS2 materials [34]. Similarly, the WS2 sample exhibits a flake shape along with a high crystalline nature of the flakes (Figure 5c, Figure 5d). Figure 5e and Figure 5f represent the MoS2/WS2 composite sample. Typical shapes and sizes corresponding to grown MoS2 and WS2 structures are also observed. High-resolution images indicate different planes corresponding to the composite sample with a corresponding d-spacing.

![[2190-4286-15-68-5]](/bjnano/content/figures/2190-4286-15-68-5.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 5: Low- and high-magnification TEM micrographs of a,b) MoS2; c,d) WS2; and e,f) MoS2/WS2 composite. g–i) High-resolution STEM-EDS mapping of the MoS2/WS2 composite depicting a random presence of W atoms (marked by circles).

Figure 5: Low- and high-magnification TEM micrographs of a,b) MoS2; c,d) WS2; and e,f) MoS2/WS2 composite. g–...

Further, scanning TEM (STEM) images along with energy-dispersive spectroscopy (EDS) mapping were carried out on the MoS2/WS2 composite. High-annular angle dark-field (HAADF-STEM) allowed the identification of atomic positions with Z differences [35,36], and in particular here, the W sites as shown in Figure 5g. This is confirmed by EDS maps of Mo and W, in Figure 5h and Figure 5i. As it can be seen, the WS2 catalyst appeared to be well embedded within the MoS2 matrix indicating a successful intermixing of both phases.

Photodegradation measurements

To examine the photocatalytic performance of MoS2 and WS2 towards the PD of MB, we first evaluated the PD of the MB dye solution under light excitation without any photocatalysts (MB photolysis) as well as its PD in the dark in the presence of a photocatalyst.

The optical absorbance spectra of the MB solution in the presence of MoS2 and WS2 were recorded in the dark and under visible light illumination at variable exposure durations. The result is displayed in Figure 6a and Figure 6b, respectively. Our findings conform with negligible PD of MB in the absence of light, as observed for both samples 30 min before PD experiments. This minimal MB concentration change recorded in the dark is likely caused by the absorption of MB by WS2 [37]. However, upon exposure to light excitation, a considerably greater PD of MB has occurred. As shown in Figure 6c (red dots), there is no direct photolysis of MB, which indicates that the degradation is mainly induced by the presence of MoS2 or WS2 catalysts. For both catalysts, no isosbestic points are observed in the optical absorption of the solution, suggesting that the MB is completely degraded without the formation of intermediary complexes.

![[2190-4286-15-68-6]](/bjnano/content/figures/2190-4286-15-68-6.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 6: PD of MB recorded under solar simulator excitation: MB absorbance variation at various durations using a) MoS2 and b) WS2 photocatalysts. The relative MB concentration change during the PD and the corresponding PD efficiency are indicated, respectively in black and blue for c) MoS2 and d) WS2 photocatalysts. The MB photolysis is amended to c) indicated in red.

Figure 6: PD of MB recorded under solar simulator excitation: MB absorbance variation at various durations us...

The following equation provides the expression of the PD efficiency at a certain light excitation duration t with respect to the MB concentration variation with time.

where C0 (mg/L) is the MB initial concentration in solution, and Ct (mg/L) is the time-dependent MB concentration obtained under light excitation. Figure 6c illustrates the changes in the concentration ratio C/C0 and the PD efficiency under visible light excitation during a 180 min period for MoS2. After 180 min of the PD experiment, the initial MB concentration was observed to decrease by 43.5% and 67.6%. in the presence of MoS2 and WS2, respectively. Further decolorization rate of MB during the photocatalysis was subsequently analyzed using the Langmuir–Hinshelwood kinetics model, expressed by the following equation:

The PD reaction rate constant, k, is the slope of Figure 7a. By plotting −ln(Ct/Co) as a function of t, it was observed that the oxidation of MB using the photocatalyst was well-fitted with the pseudo first-order reaction kinetics model [38]. Our results show a PD rate constant of 6.1 × 10−3 min−1 and 3.3 × 10−3 min−1 achieved by WS2 and MoS2, respectively.

![[2190-4286-15-68-7]](/bjnano/content/figures/2190-4286-15-68-7.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 7: Change in concentration ratio during PD experiments for a) MoS2 and c) WS2 photocatalysts and the corresponding variation of the PD rate constant (green) and PD efficiency (orange) for four cycles in the presence of b) MoS2 and d) WS2 photocatalysts.

Figure 7: Change in concentration ratio during PD experiments for a) MoS2 and c) WS2 photocatalysts and the c...

To evaluate the cyclability of our photocatalysts, we have conducted four consecutive PD runs. After each cycle (3 h), the MB dye solution was replaced with a fresh one to maintain the same initial dye concentration. This means that the remaining dye mass after each PD run was taken into account during the analysis of the results shown in Figure 7b and Figure 7d for MoS2 and WS2, respectively. To maintain the same concentration of MB, the remaining solution from run one is evaporated. By keeping the same beaker, the residual powder (WS2 or/and MoS2 + MB) is then diluted using a mixture of fresh MB solution and distilled water to obtain a solution of the same volume and concentration as the run one solution. From one run to the next one, the quantities of MB solution and distilled water required are variable and adjusted experimentally. The redilution process is controlled by the spectrophotometric absorption measurement.

Between the first and fourth cycles, the PD rate constants were observed to decrease from 3.3 min−1 to 1.8 × 10−3 min−1 and 6.1 min−1 to 2 × 10−3 min−1 in the presence of MoS2 and WS2 photocatalysts, respectively. Similarly, the PD efficiency decreased from 43.5% to 27.6% and 67.6% to 30.3% for MoS2 and WS2, respectively. These results suggest that despite the very good performance of WS2 at the first runs, MoS2 has shown a longer lifetime and stability compared to that of WS2 [39,40].

To examine the influence of MoS2 and WS2 intermixing on the PD performance, we have used MoS2/WS2 intermixing at the following ratios 20%, 40%, 60%, and 80% of WS2 toward the PD of MB with the same total amount of catalyst (i.e., 1 mg). Using the PD plots provided in Supporting Information File 1, Figures S3–S5, we extracted and plotted the PD efficiencies and the PD rate constants for all samples in Figure 8a.

![[2190-4286-15-68-8]](/bjnano/content/figures/2190-4286-15-68-8.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 8: a) PD efficiencies and PD rate-constant variations obtained under solar simulator excitation for (MoS2)x/(WS2)1−x photocatalysts at different ratios x. b) Selected (MoS2)0.2/(WS2)0.8 photocatalyst PD efficiency (orange) and its corresponding PD rate constant (green) for four cycles, the duration of each cycle is 3 h.

Figure 8: a) PD efficiencies and PD rate-constant variations obtained under solar simulator excitation for (M...

As can be seen in Figure 8a, the association of WS2 with MoS2 has a beneficial impact on the PD performance of MB of the MoS2 photocatalyst. The best performance was obtained for (MoS2)0.2/(WS2)0.8 exhibiting a PD efficiency of 60% and a PD rate constant of 5.6 × 10−3 min−1. However, the performances of MoS2/WS2 mixtures remain inferior to that of pure WS2. It can be noted that the blend practically follows the upper limit of the law of mixtures:

where XMoS2 and XWS2 are the same properties for MoS2 and WS2, and rMoS2 and rWS2 the ratios in the mixture. The 100% MoS2 showed the lowest PD performance, indicating that the photocatalytic effect of MoS2/WS2 composites is directed by the presence of WS2.

Next, we examined the recyclability of the best-performing photocatalyst MoS2/WS2 for four consecutive PD runs, each cycle lasting 3 h (Figure 8b). The result indicated an excellent long-term stability of the composite photocatalyst suggesting that the association of both MoS2 and WS2 at the appropriate content, such as (MoS2)0.2/(WS2)0.8, not only enhances the overall PD efficiency but also dramatically improves the stability and recyclability of the photocatalyst ascribed to the degradation kinetics. To mimic the real conditions, the optimized sample (MoS2)0.2/(WS2)0.8 was selected for PD experiments under direct sunlight (27 °C) in open-sky conditions. Using the same starting concentration of MB and the catalyst quantity, our results showed a higher efficiency of 66.7%, compared to the ones obtained using our solar simulator (Figure 9).

![[2190-4286-15-68-9]](/bjnano/content/figures/2190-4286-15-68-9.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 9: PD efficiency of MB recorded for (MoS2)0.2/(WS2)0.8 (blue dots) and the relative MB concentration change during the PD (black squares) using excitations from a) sunlight and b) solar simulator.

Figure 9: PD efficiency of MB recorded for (MoS2)0.2/(WS2)0.8 (blue dots) and the relative MB concentration c...

Further decolorization rate of MB during photocatalysis was subsequently analyzed using the Langmuir–Hinshelwood kinetics model as previously explained. Our results show a PD rate constant of 5.97 × 10−3 min−1 and 5.22 × 10−3 min−1 achieved under sunlight and solar simulator, respectively, as shown in Supporting Information File 1, Figure S6 and Figure S7).

Generally, the photodegradation of organic pollutants is often driven by reactive agents, such as superoxide radicals, hydroxyl radicals, or photo-induced holes produced from either the conduction or valence bands [41,42]. The mechanism of the PD of MB under visible light excitation consists of several steps: Initially, the MB dye molecules are adsorbed onto the surface of the catalyst [20], then the illumination with energy greater than that of the bandgap will promote electrons (e−) to the conduction band (CB), leaving holes (h+) in the valence band (VB). Simultaneously, oxygen molecules on the surface of the catalyst capture the excited electrons (e−), leading to the formation of superoxide anions (O2−) [43]. The adsorbed oxygen has the ability to undergo a reaction with two electrons, resulting in the formation of hydrogen peroxide (H2O2). Hydrogen peroxide subsequently reacts with an electron, forming hydroxyl radicals (•OH), which are required to drive photodegradation reaction. Concomitantly, anion groups serve as electron donors, playing a key role in the reduction process [44]. During the reaction, the VB edge potential of the sample is superior to the standard redox potentials of both •OH/OH− and •OH/H2O, suggesting that the holes build up on the VB to generate the oxidization of OH− (see Figure 10), resulting in the formation of •OH. Despite the slow oxidative hydrolysis kinetics, the oxidative radical species remain crucial to drive the photodegradation of organic pollutants [24,25].

Using the Nernst equation [45], the associated energy levels of both CB and VB can be determined. It is worth noting that identifying the ECB and EVB energy positions is important to comprehend the synergistic effects of MoS2 and WS2 in the intermixing. Hence, a linear equation is introduced to calculate the energy levels of CB and VB in both materials while taking into account their bandgap energies, as per the following equations:

where ECB is the energy level of the conduction band, EVB is the energy level of the valence band, Eg(x) and X(x) are the bandgap and the electronegativity of the respective material. E0 represents the scaling factor that establishes the connection between the absolute vacuum scale and the reference redox level (E0 = −4.5 eV). The bandgap energies used in our calculation are extracted from our previous work [27]. The obtained results are summarized in Table 1.

The following schematic diagram depicted in Figure 10 is obtained using the calculated conduction and valence bands positions. The more effective and faster electron transfer kinetics of MoS2/WS2 should account for the enhanced photocatalytic activity under irradiation.

![[2190-4286-15-68-10]](/bjnano/content/figures/2190-4286-15-68-10.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 10: Proposed PD mechanisms of MB by MoS2/WS2 catalysts.

Figure 10: Proposed PD mechanisms of MB by MoS2/WS2 catalysts.

The PD process can take place as per the following two mechanisms:

Or as follows:

The WS2/MoS2 composite exhibited significant enhancement of PD in terms of long-term stability, reaching up to 97% as shown in Figure 11 compared to that of WS2 and MoS2 taken alone. We assume this performance is ascribed to the mechanism of PD occurring in the composite sample. Precisely, when the visible light excites electrons in WS2 they transition into the CB of MoS2 due to band alignment. These photoexcited electrons then move from the CB of WS2 to MoS2, generating radical electrons that subsequently react with oxygen groups. Simultaneously, photoexcited holes spontaneously migrate from the valence band of MoS2 to WS2, potentially being captured by water molecules to form hydroxyl radicals. These hydroxyl radicals, in conjunction with valence band holes, contribute to the degradation of MB molecules into CO2 and H2O, as reported in different studies [42-44]. The effective separation of electron–hole pairs during photodegradation is facilitated by the presence of the MoS2/WS2 composite. This structure also effectively prevents the recombination of electrons and holes, ensuring an efficient photocatalytic process. In our study, we have employed the facile and cost-effective CVD processing technique to synthesize and intermix MoS2 and WS2 photocatalysts showcasing a novel approach that distinguishes our work from existing methodologies shown in Table 2, which has shown the best compromise regarding PD performance.

![[2190-4286-15-68-11]](/bjnano/content/figures/2190-4286-15-68-11.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 11: PD stability comparison between WS2, MoS2 and WS2/MoS2 composite samples.

Figure 11: PD stability comparison between WS2, MoS2 and WS2/MoS2 composite samples.

It is worth noting that despite the remarkably low catalyst loading of our CVD-based catalysts (i.e., 1 mg) the obtained PD efficiencies for both MoS2 and WS2 were relatively high, achieving 43.5% and 67.6%, respectively. This indicates the effectiveness of the CVD method in yielding high-performing photocatalysts. Table 2 compares the present work to previously reported ones. Those authors have used other mixed composites such as MoS2-GO and MoS2-ZnO prepared by the hydrothermal [22,23] method with photocatalyst loading of 10 to 100 mg, which is ten to hundredfold higher than the ones used for the current PD study.

Table 2: Reported MoS2 and WS2-based composites and their MBs photodegradation efficiency induced by solar excitation compared to this work.

| Material | Fabrication | Time (min) | Catalyst (mg) | Concentration (M) | PD % | Ref. |

| MoS2-GO | hydrothermal | 60 | 10 | 6 × 10−4 | 99% | [22] |

| MoS2-ZnO | hydrothermal | 20 | 15 | 3 × 10−5 | 97% | [23] |

| MoS2/SnO2 | hydrothermal | 5 | 20 | 10−6 | 99.5% | [24] |

| WS2/PPy | polymerization | 180 | 100 | 3 × 10−5 | 96.2% | [37] |

| MoS2/WS2 | hydrothermal | 180 | – | 10−5 | 94% | [36] |

| MoS2/WS2 | hydrothermal | 150 | 100 | 1.25 × 10−4 | 99% | [46] |

| MoS2/WS2 | hydrothermal | 90 | 25 | 1.25 × 10−4 | 85% | [47] |

| WS2@MoS2 | hydrothermal | 120 | 100 | 1.25 × 10−4 | – | [48] |

| MoS2 | CVD | 180 | 1 | 10−5 | 43.5% | this work |

| WS2 | CVD | 180 | 1 | 10−5 | 67.6% | this work |

| (MoS2)0.2/(WS2)0.8 | CVD + mixing | 180 | 1 | 10−5 | 49.6% | this work |

Furthermore, this study allowed higher stability of the catalyst when MoS2 and WS2 were mixed at 0.2 and 0.8 ratios, respectively. Indeed, we noticed that the phase intermixing induced a synergistic effect leading to an enhanced stability of the composite. The low-quantity catalyst loading emphasizes the economic and environmental advantages of our approach, making it a promising avenue for future developments in catalytic materials for pollutant degradation. Overall, these advancements underscore the superior efficacy of the presented synthesis methods, positioning them at the forefront of MoS2 and WS2 nanocomposite fabrication and paving the way for further advancements in materials science and engineering.

Conclusion

Neat and intermixed MoS2 and WS2 phases were evaluated for the PD of MB dye under solar irradiation excitation. The considered samples were systematically characterized by XPS, Raman spectroscopy, SEM, and HRTEM. WS2 exhibited the highest PD efficiency and PD rate constant of 67.6% and 6.1 × 10−3 min−1, respectively. Despite the low PD efficiency achieved, MoS2 has shown a very good PD stability of 63%. The intermixed composite (MoS2)0.2/(WS2)0.8 showed an enhancement in PD performance and long-term stability by up to 97%. Its evaluation under real conditions under sunlight showed an increased PD efficiency. Overall, our approach is cost-effective, reproducible, and can be further employed in the development of composites processed by CVD, providing a potential solution to address the growing concerns of environmental pollution.

Experimental

Both MoS2 and WS2 samples were synthesized using a one-step CVD process under atmospheric pressure. The CVD system consists of a quartz tube connected to an argon source. The furnace was gradually heated to specific processing temperatures of MoS2 and WS2, which were subsequently deposited onto SiO2/Si substrates as detailed elsewhere [27]. The fabricated samples were exfoliated in a mixed solution composed of 10 mL of ethanol, 10 mL acetone, and 10 mL of deionized water under sonication for 30 min as shown in Figure 12. Five to ten substrates loaded with the samples were used to prepare the catalyst [49]. The total obtained mass was 200 mg after the exfoliation process and sonication. The obtained material sheets were then extracted from the solution after solvent evaporation, and their mass was determined by subtracting the weight of the sample before and after exfoliation. For all PD experiments, we weighed the samples using a sensitive electronic balance (Secura microbalance, Sartorius) with an accuracy down to 0.01 mg.

![[2190-4286-15-68-12]](/bjnano/content/figures/2190-4286-15-68-12.png?scale=2.0&max-width=1024&background=FFFFFF)

Figure 12: Schematic diagram of the photocatalyst preparation.

Figure 12: Schematic diagram of the photocatalyst preparation.

Structural, crystalline, and vibrational properties of the fabricated materials were examined utilizing X-ray diffraction (D8 Discover diffractometer, Bruker) with a Kα Cu radiation source at a 1.54 Å wavelength and a micro-Raman spectrometer (Renishaw) equipped with a green laser excitation of 532 nm. The microstructure of the specimen was analyzed using a scanning electron microscope (Thermo Fisher Scientific, Waltham, MA, USA), and a transmission electron microscope (Cs-corrected Titan, Thermo Fisher Scientific). Thin carbon-coated Cu mesh grids were used to prepare TEM samples by the drop-casting method. The surface chemical bonding states and composition of the samples were determined with a scanning XPS microprobe (PHI VersaProbe III, Physical Electronics) equipped with a monochromatic and microfocused Al Kα X-ray source (1486.6 eV). During the experiment, an E-neutralizer (1 V) was implemented. The XPS spectra were calibrated using the C 1s peak position at 284.6 eV as a reference. The CasaXPS software was subsequently used for data processing. The optical properties and photodegradation experiments were conducted on a UV–vis–near IR spectrometer (JASCO V-670) and using solar simulator excitation for the PD monitoring using 10 mL of MB dye solution with a concentration of 5 mg/L (10−5 M) and 1 mg of exfoliated photocatalyst. The intensity of the optical absorption peak at 631 nm was used to monitor the concentration of MB in aqueous solution. This peak is commonly associated with photon absorption by the conjugated double bonds of MB molecules. Several measurements conducted on various MB concentrations were analyzed to obtain a correlation between the intensity of the 631 nm peak and the MB concentration. For all experiments, a first run was conducted in the dark for 30 min, followed by PD tests, and maintained for 180 min while monitored by a UV–vis spectrometer every 30 min.

Supporting Information

| Supporting Information File 1: Additional figures. | ||

| Format: PDF | Size: 921.4 KB | Download |

Data Availability Statement

The data that supports the findings of this study is available from the corresponding author upon reasonable request.

References

-

Chen, X.; Shuai, C.; Wu, Y.; Zhang, Y. Environ. Impact Assess. Rev. 2021, 90, 106609. doi:10.1016/j.eiar.2021.106609

Return to citation in text: [1] -

Yang, D.; Yang, Y.; Xia, J. Geogr. Sustainability 2021, 2, 115–122. doi:10.1016/j.geosus.2021.05.003

Return to citation in text: [1] -

Hao, L.; Ju, P.; Zhang, Y.; Zhai, X.; Sun, C.; Duan, J.; Su, Y.; Lu, Z.; Liao, D. Colloids Surf., A 2021, 610, 125714. doi:10.1016/j.colsurfa.2020.125714

Return to citation in text: [1] -

Pandey, S.; Fosso-Kankeu, E.; Spiro, M. J.; Waanders, F.; Kumar, N.; Ray, S. S.; Kim, J.; Kang, M. Mater. Today Chem. 2020, 18, 100376. doi:10.1016/j.mtchem.2020.100376

Return to citation in text: [1] -

Shahid, M. K.; Kashif, A.; Fuwad, A.; Choi, Y. Coord. Chem. Rev. 2021, 442, 213993. doi:10.1016/j.ccr.2021.213993

Return to citation in text: [1] -

Soares, S. F.; Fernandes, T.; Trindade, T.; Daniel-da-Silva, A. L. Environ. Chem. Lett. 2020, 18, 151–164. doi:10.1007/s10311-019-00931-8

Return to citation in text: [1] -

Mohammed, M. A.; Shitu, A.; Ibrahim, A. Res. J. Chem. Sci. 2014, 4 (1), 91–102.

http://www.isca.me/rjcs/Archives/v4/i1/15.ISCA-RJCS-2013-178.php

Return to citation in text: [1] -

Hassanpour, M.; Safardoust-Hojaghan, H.; Salavati-Niasari, M. J. Mol. Liq. 2017, 229, 293–299. doi:10.1016/j.molliq.2016.12.090

Return to citation in text: [1] [2] -

Binazadeh, M.; Rasouli, J.; Sabbaghi, S.; Mousavi, S. M.; Hashemi, S. A.; Lai, C. W. Materials 2023, 16, 3526. doi:10.3390/ma16093526

Return to citation in text: [1] [2] -

Chen, C.; Ma, W.; Zhao, J. Chem. Soc. Rev. 2010, 39, 4206–4219. doi:10.1039/b921692h

Return to citation in text: [1] [2] -

Pirhashemi, M.; Habibi-Yangjeh, A.; Rahim Pouran, S. J. Ind. Eng. Chem. (Amsterdam, Neth.) 2018, 62, 1–25. doi:10.1016/j.jiec.2018.01.012

Return to citation in text: [1] -

Zong, X.; Yan, H.; Wu, G.; Ma, G.; Wen, F.; Wang, L.; Li, C. J. Am. Chem. Soc. 2008, 130, 7176–7177. doi:10.1021/ja8007825

Return to citation in text: [1] -

Chang, K.; Hai, X.; Ye, J. Adv. Energy Mater. 2016, 6, 1502555. doi:10.1002/aenm.201502555

Return to citation in text: [1] -

Bhandavat, R.; David, L.; Singh, G. J. Phys. Chem. Lett. 2012, 3, 1523–1530. doi:10.1021/jz300480w

Return to citation in text: [1] -

Lu, Q.; Yu, Y.; Ma, Q.; Chen, B.; Zhang, H. Adv. Mater. (Weinheim, Ger.) 2016, 28, 1917–1933. doi:10.1002/adma.201503270

Return to citation in text: [1] -

Chen, S.; Takata, T.; Domen, K. Nat. Rev. Mater. 2017, 2, 17050. doi:10.1038/natrevmats.2017.50

Return to citation in text: [1] -

Liang, Z.; Shen, R.; Ng, Y. H.; Fu, Y.; Ma, T.; Zhang, P.; Li, Y.; Li, X. Chem Catal. 2022, 2, 2157–2228. doi:10.1016/j.checat.2022.06.006

Return to citation in text: [1] -

Yang, R.; Fan, Y.; Zhang, Y.; Mei, L.; Zhu, R.; Qin, J.; Hu, J.; Chen, Z.; Hau Ng, Y.; Voiry, D.; Li, S.; Lu, Q.; Wang, Q.; Yu, J. C.; Zeng, Z. Angew. Chem., Int. Ed. 2023, 62, e202218016. doi:10.1002/anie.202218016

Return to citation in text: [1] -

Ahmaruzzaman, M.; Gadore, V. J. Environ. Chem. Eng. 2021, 9, 105836. doi:10.1016/j.jece.2021.105836

Return to citation in text: [1] -

Joseph, A.; Aneesh, P. M. Mater. Res. Bull. 2022, 146, 111623. doi:10.1016/j.materresbull.2021.111623

Return to citation in text: [1] [2] -

Amaral, L. O.; Daniel-da-Silva, A. L. Molecules 2022, 27, 6782. doi:10.3390/molecules27206782

Return to citation in text: [1] -

Ding, Y.; Zhou, Y.; Nie, W.; Chen, P. Appl. Surf. Sci. 2015, 357, 1606–1612. doi:10.1016/j.apsusc.2015.10.030

Return to citation in text: [1] [2] [3] -

Ritika; Kaur, M.; Umar, A.; Mehta, S. K.; Singh, S.; Kansal, S. K.; Fouad, H.; Alothman, O. Y. Materials 2018, 11, 2254. doi:10.3390/ma11112254

Return to citation in text: [1] [2] [3] -

Szkoda, M.; Zarach, Z.; Nadolska, M.; Trykowski, G.; Trzciński, K. Electrochim. Acta 2022, 414, 140173. doi:10.1016/j.electacta.2022.140173

Return to citation in text: [1] [2] [3] -

Kaur, N.; Singh, M.; Moumen, A.; Duina, G.; Comini, E. Materials 2020, 13, 2974. doi:10.3390/ma13132974

Return to citation in text: [1] [2] [3] -

Marmolejo-Tejada, J. M.; Fix, J. P.; Kung, P.; Borys, N. J.; Mosquera, M. A. J. Phys. Chem. C 2022, 126, 9099–9108. doi:10.1021/acs.jpcc.2c01535

Return to citation in text: [1] -

Turner, N. H.; Single, A. M. Surf. Interface Anal. 1990, 15, 215–222. doi:10.1002/sia.740150305

Return to citation in text: [1] [2] [3] -

Ji, H.; Hu, S.; Shi, S.; Guo, B.; Hou, W.; Yang, G. J. Mater. Sci. 2018, 53, 14548–14558. doi:10.1007/s10853-018-2631-7

Return to citation in text: [1] [2] -

Li, B.; Jiang, L.; Li, X.; Ran, P.; Zuo, P.; Wang, A.; Qu, L.; Zhao, Y.; Cheng, Z.; Lu, Y. Sci. Rep. 2017, 7, 11182. doi:10.1038/s41598-017-10632-3

Return to citation in text: [1] -

Mouloua, D.; LeBlanc‐Lavoie, J.; Pichon, L.; Rajput, N. S.; El Marssi, M.; Jouiad, M.; El Khakani, M. A. Adv. Opt. Mater. 2024, 12, 2302966. doi:10.1002/adom.202302966

Return to citation in text: [1] -

Mao, X.; Xu, Y.; Xue, Q.; Wang, W.; Gao, D. Nanoscale Res. Lett. 2013, 8, 430. doi:10.1186/1556-276x-8-430

Return to citation in text: [1] [2] [3] -

Al Qaydi, M.; Kotbi, A.; Rajput, N. S.; Bouchalkha, A.; El Marssi, M.; Matras, G.; Kasmi, C.; Jouiad, M. Nanomaterials 2022, 13, 24. doi:10.3390/nano13010024

Return to citation in text: [1] -

Ochedowski, O.; Marinov, K.; Scheuschner, N.; Poloczek, A.; Bussmann, B. K.; Maultzsch, J.; Schleberger, M. Beilstein J. Nanotechnol. 2014, 5, 291–297. doi:10.3762/bjnano.5.32

Return to citation in text: [1] -

Rajput, N. S.; Sloyan, K.; Anjum, D. H.; Chiesa, M.; Al Ghaferi, A. Ultramicroscopy 2022, 235, 113496. doi:10.1016/j.ultramic.2022.113496

Return to citation in text: [1] -

Gong, K.; Lou, W.; Zhao, G.; Wu, X.; Wang, X. Friction 2020, 8, 674–683. doi:10.1007/s40544-019-0290-6

Return to citation in text: [1] -

Aswal, D.; Bamola, P.; Rani, C.; Rawat, S.; Bhatt, A.; Chhoker, S.; Sharma, M.; Dwivedi, C.; Kumar, R.; Sharma, H. ChemistrySelect 2023, 8, e202204998. doi:10.1002/slct.202204998

Return to citation in text: [1] [2] -

Shahabuddin, S.; Mehmood, S.; Ahmad, I.; Sridewi, N. Nanomaterials 2022, 12, 2090. doi:10.3390/nano12122090

Return to citation in text: [1] [2] -

Jawad, A. H.; Mubarak, N. S. A.; Ishak, M. A. M.; Ismail, K.; Nawawi, W. I. J. Taibah Univ. Sci. 2016, 10, 352–362. doi:10.1016/j.jtusci.2015.03.007

Return to citation in text: [1] -

Rajput, N. S.; Kotbi, A.; Kaja, K.; Jouiad, M. npj Mater. Degrad. 2022, 6, 75. doi:10.1038/s41529-022-00288-4

Return to citation in text: [1] -

Deokar, G.; Rajput, N. S.; Li, J.; Deepak, F. L.; Ou-Yang, W.; Reckinger, N.; Bittencourt, C.; Colomer, J.-F.; Jouiad, M. Beilstein J. Nanotechnol. 2018, 9, 1686–1694. doi:10.3762/bjnano.9.160

Return to citation in text: [1] -

Rajput, N. S.; Shao-Horn, Y.; Li, X.-H.; Kim, S.-G.; Jouiad, M. Phys. Chem. Chem. Phys. 2017, 19, 16989–16999. doi:10.1039/c7cp03212a

Return to citation in text: [1] -

Rajput, N. S.; Baik, H.; Lu, J.-Y.; Tamalampudi, S. R.; Sankar, R.; Al Ghaferi, A.; Chiesa, M. J. Phys. Chem. C 2021, 125, 9956–9964. doi:10.1021/acs.jpcc.0c10756

Return to citation in text: [1] [2] -

Ji, Q.; Zhang, Y.; Gao, T.; Zhang, Y.; Ma, D.; Liu, M.; Chen, Y.; Qiao, X.; Tan, P.-H.; Kan, M.; Feng, J.; Sun, Q.; Liu, Z. Nano Lett. 2013, 13, 3870–3877. doi:10.1021/nl401938t

Return to citation in text: [1] [2] -

Wu, Y.; Gao, Z.; Sun, X.; Cai, H.; Wu, X. J. Environ. Sci. 2021, 101, 145–155. doi:10.1016/j.jes.2020.08.014

Return to citation in text: [1] [2] -

Sharma, R.; Uma; Singh, S.; Verma, A.; Khanuja, M. J. Photochem. Photobiol., B 2016, 162, 266–272. doi:10.1016/j.jphotobiol.2016.06.035

Return to citation in text: [1] -

Zhao, Y.; Liu, J.; Zhang, X.; Wang, C.; Zhao, X.; Li, J.; Jin, H. J. Phys. Chem. C 2019, 123, 27363–27368. doi:10.1021/acs.jpcc.9b08101

Return to citation in text: [1] -

Luo, S.; Dong, S.; Lu, C.; Yu, C.; Ou, Y.; Luo, L.; Sun, J.; Sun, J. J. Colloid Interface Sci. 2018, 513, 389–399. doi:10.1016/j.jcis.2017.11.044

Return to citation in text: [1] -

Li, H.; Yu, K.; Li, C.; Guo, B.; Lei, X.; Fu, H.; Zhu, Z. J. Mater. Chem. A 2015, 3, 20225–20235. doi:10.1039/c5ta05283a

Return to citation in text: [1] -

Mouloua, D.; Lejeune, M.; Rajput, N. S.; Kaja, K.; El Marssi, M.; El Khakani, M. A.; Jouiad, M. Ultrason. Sonochem. 2023, 95, 106381. doi:10.1016/j.ultsonch.2023.106381

Return to citation in text: [1]

| 33. | Ochedowski, O.; Marinov, K.; Scheuschner, N.; Poloczek, A.; Bussmann, B. K.; Maultzsch, J.; Schleberger, M. Beilstein J. Nanotechnol. 2014, 5, 291–297. doi:10.3762/bjnano.5.32 |

| 34. | Rajput, N. S.; Sloyan, K.; Anjum, D. H.; Chiesa, M.; Al Ghaferi, A. Ultramicroscopy 2022, 235, 113496. doi:10.1016/j.ultramic.2022.113496 |

| 35. | Gong, K.; Lou, W.; Zhao, G.; Wu, X.; Wang, X. Friction 2020, 8, 674–683. doi:10.1007/s40544-019-0290-6 |

| 36. | Aswal, D.; Bamola, P.; Rani, C.; Rawat, S.; Bhatt, A.; Chhoker, S.; Sharma, M.; Dwivedi, C.; Kumar, R.; Sharma, H. ChemistrySelect 2023, 8, e202204998. doi:10.1002/slct.202204998 |

| 44. | Wu, Y.; Gao, Z.; Sun, X.; Cai, H.; Wu, X. J. Environ. Sci. 2021, 101, 145–155. doi:10.1016/j.jes.2020.08.014 |

| 24. | Szkoda, M.; Zarach, Z.; Nadolska, M.; Trykowski, G.; Trzciński, K. Electrochim. Acta 2022, 414, 140173. doi:10.1016/j.electacta.2022.140173 |

| 25. | Kaur, N.; Singh, M.; Moumen, A.; Duina, G.; Comini, E. Materials 2020, 13, 2974. doi:10.3390/ma13132974 |

| 20. | Joseph, A.; Aneesh, P. M. Mater. Res. Bull. 2022, 146, 111623. doi:10.1016/j.materresbull.2021.111623 |

| 43. | Ji, Q.; Zhang, Y.; Gao, T.; Zhang, Y.; Ma, D.; Liu, M.; Chen, Y.; Qiao, X.; Tan, P.-H.; Kan, M.; Feng, J.; Sun, Q.; Liu, Z. Nano Lett. 2013, 13, 3870–3877. doi:10.1021/nl401938t |

| 39. | Rajput, N. S.; Kotbi, A.; Kaja, K.; Jouiad, M. npj Mater. Degrad. 2022, 6, 75. doi:10.1038/s41529-022-00288-4 |

| 40. | Deokar, G.; Rajput, N. S.; Li, J.; Deepak, F. L.; Ou-Yang, W.; Reckinger, N.; Bittencourt, C.; Colomer, J.-F.; Jouiad, M. Beilstein J. Nanotechnol. 2018, 9, 1686–1694. doi:10.3762/bjnano.9.160 |

| 41. | Rajput, N. S.; Shao-Horn, Y.; Li, X.-H.; Kim, S.-G.; Jouiad, M. Phys. Chem. Chem. Phys. 2017, 19, 16989–16999. doi:10.1039/c7cp03212a |

| 42. | Rajput, N. S.; Baik, H.; Lu, J.-Y.; Tamalampudi, S. R.; Sankar, R.; Al Ghaferi, A.; Chiesa, M. J. Phys. Chem. C 2021, 125, 9956–9964. doi:10.1021/acs.jpcc.0c10756 |

| 37. | Shahabuddin, S.; Mehmood, S.; Ahmad, I.; Sridewi, N. Nanomaterials 2022, 12, 2090. doi:10.3390/nano12122090 |

| 38. | Jawad, A. H.; Mubarak, N. S. A.; Ishak, M. A. M.; Ismail, K.; Nawawi, W. I. J. Taibah Univ. Sci. 2016, 10, 352–362. doi:10.1016/j.jtusci.2015.03.007 |

| 45. | Sharma, R.; Uma; Singh, S.; Verma, A.; Khanuja, M. J. Photochem. Photobiol., B 2016, 162, 266–272. doi:10.1016/j.jphotobiol.2016.06.035 |

| 27. | Turner, N. H.; Single, A. M. Surf. Interface Anal. 1990, 15, 215–222. doi:10.1002/sia.740150305 |

| 42. | Rajput, N. S.; Baik, H.; Lu, J.-Y.; Tamalampudi, S. R.; Sankar, R.; Al Ghaferi, A.; Chiesa, M. J. Phys. Chem. C 2021, 125, 9956–9964. doi:10.1021/acs.jpcc.0c10756 |

| 43. | Ji, Q.; Zhang, Y.; Gao, T.; Zhang, Y.; Ma, D.; Liu, M.; Chen, Y.; Qiao, X.; Tan, P.-H.; Kan, M.; Feng, J.; Sun, Q.; Liu, Z. Nano Lett. 2013, 13, 3870–3877. doi:10.1021/nl401938t |

| 44. | Wu, Y.; Gao, Z.; Sun, X.; Cai, H.; Wu, X. J. Environ. Sci. 2021, 101, 145–155. doi:10.1016/j.jes.2020.08.014 |

| 46. | Zhao, Y.; Liu, J.; Zhang, X.; Wang, C.; Zhao, X.; Li, J.; Jin, H. J. Phys. Chem. C 2019, 123, 27363–27368. doi:10.1021/acs.jpcc.9b08101 |

| 47. | Luo, S.; Dong, S.; Lu, C.; Yu, C.; Ou, Y.; Luo, L.; Sun, J.; Sun, J. J. Colloid Interface Sci. 2018, 513, 389–399. doi:10.1016/j.jcis.2017.11.044 |

| 37. | Shahabuddin, S.; Mehmood, S.; Ahmad, I.; Sridewi, N. Nanomaterials 2022, 12, 2090. doi:10.3390/nano12122090 |

| 36. | Aswal, D.; Bamola, P.; Rani, C.; Rawat, S.; Bhatt, A.; Chhoker, S.; Sharma, M.; Dwivedi, C.; Kumar, R.; Sharma, H. ChemistrySelect 2023, 8, e202204998. doi:10.1002/slct.202204998 |

| 23. | Ritika; Kaur, M.; Umar, A.; Mehta, S. K.; Singh, S.; Kansal, S. K.; Fouad, H.; Alothman, O. Y. Materials 2018, 11, 2254. doi:10.3390/ma11112254 |

| 24. | Szkoda, M.; Zarach, Z.; Nadolska, M.; Trykowski, G.; Trzciński, K. Electrochim. Acta 2022, 414, 140173. doi:10.1016/j.electacta.2022.140173 |

| 22. | Ding, Y.; Zhou, Y.; Nie, W.; Chen, P. Appl. Surf. Sci. 2015, 357, 1606–1612. doi:10.1016/j.apsusc.2015.10.030 |

| 23. | Ritika; Kaur, M.; Umar, A.; Mehta, S. K.; Singh, S.; Kansal, S. K.; Fouad, H.; Alothman, O. Y. Materials 2018, 11, 2254. doi:10.3390/ma11112254 |

| 22. | Ding, Y.; Zhou, Y.; Nie, W.; Chen, P. Appl. Surf. Sci. 2015, 357, 1606–1612. doi:10.1016/j.apsusc.2015.10.030 |

| 27. | Turner, N. H.; Single, A. M. Surf. Interface Anal. 1990, 15, 215–222. doi:10.1002/sia.740150305 |

| 49. | Mouloua, D.; Lejeune, M.; Rajput, N. S.; Kaja, K.; El Marssi, M.; El Khakani, M. A.; Jouiad, M. Ultrason. Sonochem. 2023, 95, 106381. doi:10.1016/j.ultsonch.2023.106381 |

| 48. | Li, H.; Yu, K.; Li, C.; Guo, B.; Lei, X.; Fu, H.; Zhu, Z. J. Mater. Chem. A 2015, 3, 20225–20235. doi:10.1039/c5ta05283a |

| 1. | Chen, X.; Shuai, C.; Wu, Y.; Zhang, Y. Environ. Impact Assess. Rev. 2021, 90, 106609. doi:10.1016/j.eiar.2021.106609 |

| 2. | Yang, D.; Yang, Y.; Xia, J. Geogr. Sustainability 2021, 2, 115–122. doi:10.1016/j.geosus.2021.05.003 |

| 8. | Hassanpour, M.; Safardoust-Hojaghan, H.; Salavati-Niasari, M. J. Mol. Liq. 2017, 229, 293–299. doi:10.1016/j.molliq.2016.12.090 |

| 22. | Ding, Y.; Zhou, Y.; Nie, W.; Chen, P. Appl. Surf. Sci. 2015, 357, 1606–1612. doi:10.1016/j.apsusc.2015.10.030 |

| 7. |

Mohammed, M. A.; Shitu, A.; Ibrahim, A. Res. J. Chem. Sci. 2014, 4 (1), 91–102.

http://www.isca.me/rjcs/Archives/v4/i1/15.ISCA-RJCS-2013-178.php |

| 23. | Ritika; Kaur, M.; Umar, A.; Mehta, S. K.; Singh, S.; Kansal, S. K.; Fouad, H.; Alothman, O. Y. Materials 2018, 11, 2254. doi:10.3390/ma11112254 |

| 4. | Pandey, S.; Fosso-Kankeu, E.; Spiro, M. J.; Waanders, F.; Kumar, N.; Ray, S. S.; Kim, J.; Kang, M. Mater. Today Chem. 2020, 18, 100376. doi:10.1016/j.mtchem.2020.100376 |

| 5. | Shahid, M. K.; Kashif, A.; Fuwad, A.; Choi, Y. Coord. Chem. Rev. 2021, 442, 213993. doi:10.1016/j.ccr.2021.213993 |

| 6. | Soares, S. F.; Fernandes, T.; Trindade, T.; Daniel-da-Silva, A. L. Environ. Chem. Lett. 2020, 18, 151–164. doi:10.1007/s10311-019-00931-8 |

| 21. | Amaral, L. O.; Daniel-da-Silva, A. L. Molecules 2022, 27, 6782. doi:10.3390/molecules27206782 |

| 3. | Hao, L.; Ju, P.; Zhang, Y.; Zhai, X.; Sun, C.; Duan, J.; Su, Y.; Lu, Z.; Liao, D. Colloids Surf., A 2021, 610, 125714. doi:10.1016/j.colsurfa.2020.125714 |

| 8. | Hassanpour, M.; Safardoust-Hojaghan, H.; Salavati-Niasari, M. J. Mol. Liq. 2017, 229, 293–299. doi:10.1016/j.molliq.2016.12.090 |

| 9. | Binazadeh, M.; Rasouli, J.; Sabbaghi, S.; Mousavi, S. M.; Hashemi, S. A.; Lai, C. W. Materials 2023, 16, 3526. doi:10.3390/ma16093526 |

| 10. | Chen, C.; Ma, W.; Zhao, J. Chem. Soc. Rev. 2010, 39, 4206–4219. doi:10.1039/b921692h |

| 14. | Bhandavat, R.; David, L.; Singh, G. J. Phys. Chem. Lett. 2012, 3, 1523–1530. doi:10.1021/jz300480w |

| 15. | Lu, Q.; Yu, Y.; Ma, Q.; Chen, B.; Zhang, H. Adv. Mater. (Weinheim, Ger.) 2016, 28, 1917–1933. doi:10.1002/adma.201503270 |

| 18. | Yang, R.; Fan, Y.; Zhang, Y.; Mei, L.; Zhu, R.; Qin, J.; Hu, J.; Chen, Z.; Hau Ng, Y.; Voiry, D.; Li, S.; Lu, Q.; Wang, Q.; Yu, J. C.; Zeng, Z. Angew. Chem., Int. Ed. 2023, 62, e202218016. doi:10.1002/anie.202218016 |

| 12. | Zong, X.; Yan, H.; Wu, G.; Ma, G.; Wen, F.; Wang, L.; Li, C. J. Am. Chem. Soc. 2008, 130, 7176–7177. doi:10.1021/ja8007825 |

| 13. | Chang, K.; Hai, X.; Ye, J. Adv. Energy Mater. 2016, 6, 1502555. doi:10.1002/aenm.201502555 |

| 19. | Ahmaruzzaman, M.; Gadore, V. J. Environ. Chem. Eng. 2021, 9, 105836. doi:10.1016/j.jece.2021.105836 |

| 20. | Joseph, A.; Aneesh, P. M. Mater. Res. Bull. 2022, 146, 111623. doi:10.1016/j.materresbull.2021.111623 |

| 10. | Chen, C.; Ma, W.; Zhao, J. Chem. Soc. Rev. 2010, 39, 4206–4219. doi:10.1039/b921692h |

| 11. | Pirhashemi, M.; Habibi-Yangjeh, A.; Rahim Pouran, S. J. Ind. Eng. Chem. (Amsterdam, Neth.) 2018, 62, 1–25. doi:10.1016/j.jiec.2018.01.012 |

| 9. | Binazadeh, M.; Rasouli, J.; Sabbaghi, S.; Mousavi, S. M.; Hashemi, S. A.; Lai, C. W. Materials 2023, 16, 3526. doi:10.3390/ma16093526 |

| 16. | Chen, S.; Takata, T.; Domen, K. Nat. Rev. Mater. 2017, 2, 17050. doi:10.1038/natrevmats.2017.50 |

| 17. | Liang, Z.; Shen, R.; Ng, Y. H.; Fu, Y.; Ma, T.; Zhang, P.; Li, Y.; Li, X. Chem Catal. 2022, 2, 2157–2228. doi:10.1016/j.checat.2022.06.006 |

| 25. | Kaur, N.; Singh, M.; Moumen, A.; Duina, G.; Comini, E. Materials 2020, 13, 2974. doi:10.3390/ma13132974 |

| 24. | Szkoda, M.; Zarach, Z.; Nadolska, M.; Trykowski, G.; Trzciński, K. Electrochim. Acta 2022, 414, 140173. doi:10.1016/j.electacta.2022.140173 |

| 25. | Kaur, N.; Singh, M.; Moumen, A.; Duina, G.; Comini, E. Materials 2020, 13, 2974. doi:10.3390/ma13132974 |

| 31. | Mao, X.; Xu, Y.; Xue, Q.; Wang, W.; Gao, D. Nanoscale Res. Lett. 2013, 8, 430. doi:10.1186/1556-276x-8-430 |

| 32. | Al Qaydi, M.; Kotbi, A.; Rajput, N. S.; Bouchalkha, A.; El Marssi, M.; Matras, G.; Kasmi, C.; Jouiad, M. Nanomaterials 2022, 13, 24. doi:10.3390/nano13010024 |

| 31. | Mao, X.; Xu, Y.; Xue, Q.; Wang, W.; Gao, D. Nanoscale Res. Lett. 2013, 8, 430. doi:10.1186/1556-276x-8-430 |

| 31. | Mao, X.; Xu, Y.; Xue, Q.; Wang, W.; Gao, D. Nanoscale Res. Lett. 2013, 8, 430. doi:10.1186/1556-276x-8-430 |

| 28. | Ji, H.; Hu, S.; Shi, S.; Guo, B.; Hou, W.; Yang, G. J. Mater. Sci. 2018, 53, 14548–14558. doi:10.1007/s10853-018-2631-7 |

| 30. | Mouloua, D.; LeBlanc‐Lavoie, J.; Pichon, L.; Rajput, N. S.; El Marssi, M.; Jouiad, M.; El Khakani, M. A. Adv. Opt. Mater. 2024, 12, 2302966. doi:10.1002/adom.202302966 |

| 26. | Marmolejo-Tejada, J. M.; Fix, J. P.; Kung, P.; Borys, N. J.; Mosquera, M. A. J. Phys. Chem. C 2022, 126, 9099–9108. doi:10.1021/acs.jpcc.2c01535 |

| 27. | Turner, N. H.; Single, A. M. Surf. Interface Anal. 1990, 15, 215–222. doi:10.1002/sia.740150305 |

| 28. | Ji, H.; Hu, S.; Shi, S.; Guo, B.; Hou, W.; Yang, G. J. Mater. Sci. 2018, 53, 14548–14558. doi:10.1007/s10853-018-2631-7 |

| 29. | Li, B.; Jiang, L.; Li, X.; Ran, P.; Zuo, P.; Wang, A.; Qu, L.; Zhao, Y.; Cheng, Z.; Lu, Y. Sci. Rep. 2017, 7, 11182. doi:10.1038/s41598-017-10632-3 |

© 2024 Al Qaydi et al.; licensee Beilstein-Institut.

This is an open access article licensed under the terms of the Beilstein-Institut Open Access License Agreement (https://www.beilstein-journals.org/bjnano/terms), which is identical to the Creative Commons Attribution 4.0 International License (https://creativecommons.org/licenses/by/4.0). The reuse of material under this license requires that the author(s), source and license are credited. Third-party material in this article could be subject to other licenses (typically indicated in the credit line), and in this case, users are required to obtain permission from the license holder to reuse the material.